Those collets (the more taper type) fit directly in the spindle taper. The drilled and tapped to accept a drawbar (which you will probably have build yourself). I would also recommend getting some anti-seize lubricant to put on the outside of the taper and the drawbar threads. Don't tighten the drawbar too tight; morse tapers lock in pretty hard, and if you crank down too hard, you are really going to have to beat on the collet to get it out (which isn't great for your spindle bearings).

The reason the max size on the mt2 collets is so small is that mt2 itself is pretty small. I think that these are mostly used for holding endmills when milling on the lathe, or for mills that have a morse taper spindle. There is no real reason they could not be used for workholding though.

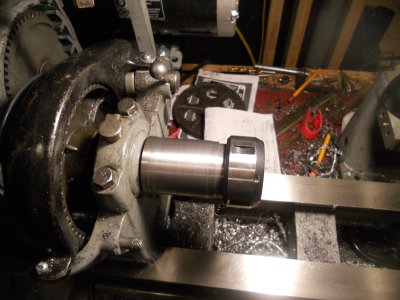

There are other types that can be used. One popular solution is to get a ER collet holder with an mt2 shank. This is a more expensive solution, but collets are available in a greater range.

As far as accuracy, they are neither more or less accurate than a chuck (in general), but they do have their uses. In general (of course, it depends on the relative quality of the tooling), they have a lower TIR (Total Indicator Runout) than a 3 jaw chuck. They also tend to have good repeatability (they clamp the same way every time). Another benefit is that they do not tend to mar the work because the clamping load is distributed evenly. Disadvantages are they they tend to be more expensive, and some (like mt2, 5c, R-8) have a relatively small clamping range, so you need a lot of them to handle a wide range of stock. The place where collets excel is when you are making a bunch of things of the same size, and you are using reasonably accurate stock. They are used in production quite frequently in turret lathes.

Perhaps the most accurate methods are turning between centers, and 4 jaw independent chucks. 4 jaw chucks are more time consuming to use because each part must be "dialed" in with an indicator to center it. You can achieve arbitrary levels of accuracy though (limited only by your measurement equipment and patience). To avoid marring the work, copper or aluminum shims are often placed between the jaws and the part.