- Joined

- May 7, 2014

- Messages

- 776

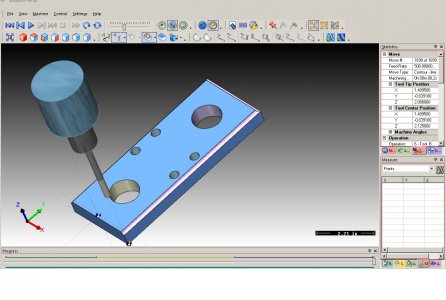

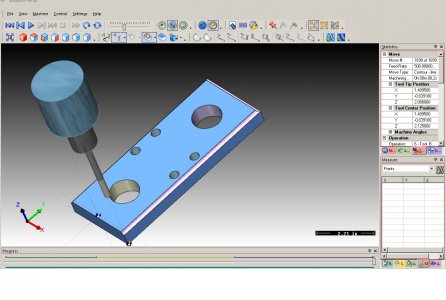

I have the next CNC job CAM /Gcode for my Plasma torch holder setup. The job is to Mill several holes thru 1/2" aluminum. holes are .375 to 1.25 (pocketing routines). I have wood under the part to act as sacrifice material. ( will go .125 or so beyond the aluminum bottom).

Then there is the dressing w/ a chamfer along the outside top edge. ( I just like them.... dunno why ;-)

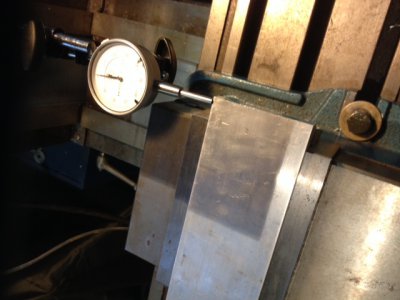

We want to do this all in 1 set of Ops if possible to keep the edge alignment. I see similar setups online, in vids, even here look like this - But that does not always make it right or safe.

Being new to part setups in the new vise; Is it OK to put the Aluminum part up & out of the Vise like this to allow the holes and then room for the chamfer edge op? Or should I just bolt it down to the table to run a 2nd setup and ops for the chamfer? End mill is a 1/4" to keep the forces down. (if that even helps?).

thanks everyone,

CG and Son.

Then there is the dressing w/ a chamfer along the outside top edge. ( I just like them.... dunno why ;-)

We want to do this all in 1 set of Ops if possible to keep the edge alignment. I see similar setups online, in vids, even here look like this - But that does not always make it right or safe.

Being new to part setups in the new vise; Is it OK to put the Aluminum part up & out of the Vise like this to allow the holes and then room for the chamfer edge op? Or should I just bolt it down to the table to run a 2nd setup and ops for the chamfer? End mill is a 1/4" to keep the forces down. (if that even helps?).

thanks everyone,

CG and Son.