- Joined

- Jan 26, 2016

- Messages

- 5

Hey I am hoping someone with a little more experience can help coach me on a successful CNC conversion of my knee mill. I have lots of experience machining and almost no experience with electronics. This is the mill I have. It is also sold by grizzly with the name g3617

I found a kit someone has purchased for a CNC conversion that they never finished. It was really cheap so I just bought the whole set up with out researching it or testing it.

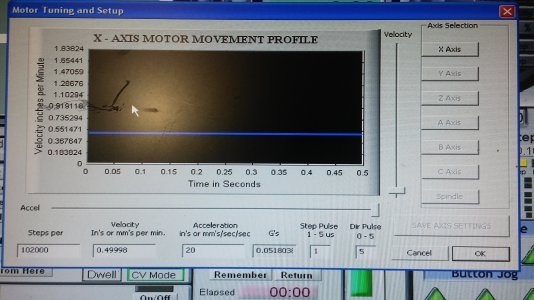

I have a computer with mach3, a break outboard, 3 drivers and a power supply that is all wired up but nothing is configured properly and is still untested. This is what I was thinking for driving the original acme lead screws. The 2 biggest questions are will the stepper motors be big enough? and how do I set up the drivers? plus any suggestions on my construction would be appreciated.

This is a mock up of my timing belt. you can see it is a 2:1 ratio because I suspect I may not have enough torque with these motors?

The steppers and the drivers are made by Wantai. I don't know how I am going to do Z yet? I suspect I may need to CNC the quill and move the knee manually

I found a kit someone has purchased for a CNC conversion that they never finished. It was really cheap so I just bought the whole set up with out researching it or testing it.

I have a computer with mach3, a break outboard, 3 drivers and a power supply that is all wired up but nothing is configured properly and is still untested. This is what I was thinking for driving the original acme lead screws. The 2 biggest questions are will the stepper motors be big enough? and how do I set up the drivers? plus any suggestions on my construction would be appreciated.

This is a mock up of my timing belt. you can see it is a 2:1 ratio because I suspect I may not have enough torque with these motors?

The steppers and the drivers are made by Wantai. I don't know how I am going to do Z yet? I suspect I may need to CNC the quill and move the knee manually