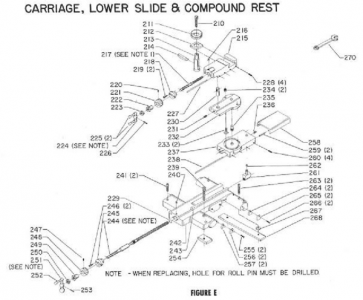

So I'm finally putting together my Clausing lathe after a move from NY - everything was going well until I got to the saddle. On this machine the saddle has a gib between the saddle and bed on the rear of the saddle. The gib attaches to the saddle and rides on the underside of the bed. On the front of the bed there is, according to the parts list, a registration bar that also attaches tot he saddle and rides on the underside of the bed. My machine came to me with two shims between the registration bar and the saddle. When I assemble all of this I am getting some lift on the front of the saddle - lift in terms of there is movement of the saddle upo and down when I lift the front of it.

My assumption is that there should not be any movement of the saddle when the gib and registration bar are assembled. I removed both shims from the registration bar thinking that would tighten it up but it still had movement.

So first question - is my assumption right that the saddle should not move up and down when assembled? If so is here an adjustment for this problem?

Thanks

Rick

My assumption is that there should not be any movement of the saddle when the gib and registration bar are assembled. I removed both shims from the registration bar thinking that would tighten it up but it still had movement.

So first question - is my assumption right that the saddle should not move up and down when assembled? If so is here an adjustment for this problem?

Thanks

Rick