- Joined

- Jun 12, 2014

- Messages

- 4,808

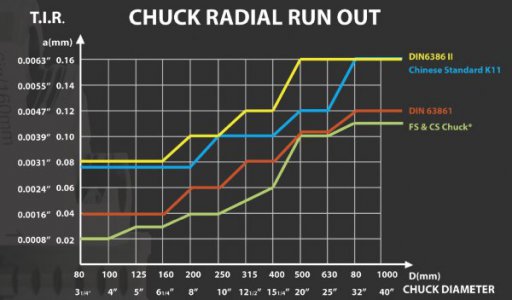

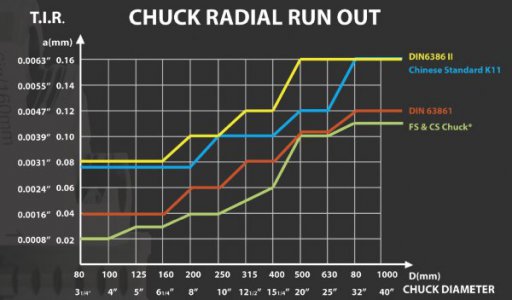

Had a recent email flyer from Shar's that outlined the chuck radial run out and the different standards. I thought it would interesting to post, as there is often the discussion about expected TIR of different chucks. The TIR is dependent on the manufacturer guaranteed specs (QC), size/type of chuck and if it uses some form of Set-Tru type system. One also needs to factor in the back plate and if it is trued up on the machine. Given that Enco is gone, and a few of the other vendors that sold chucks, the options seem to be more limited these days. I have had my share of generic Chinese chucks, most either where returned or sit on a shelf because of TIR or clamping alignment issues. They probably could be fixed with some TLC, but I do not have the inclination to deal with them.

Anyway, the new Shar's chucks seem to offer decent quality and some pretty tight tolerances at decent prices, the Gator/Feruda can be hit or miss but seem to work well, and I have read a few older posts where there have been an issue with the Bison chucks. I do a lot of repeat turning and currently run the Bison Set-Tru 5C, their 8" combination 4J and have been very happy with both of them, also have a Pratt Burnerd SetRite 6" chuck. The PB is also great chuck, The adjustable chucks hold a repeat TIR of better than 0.0004", the combo chuck can be zeroed in less than a minute with repeat parts. The new Shar's FS and CS might be worth considering at a lower price break, they also have their Zero-Set adjustable chucks. I also have a 4J Taiwanese independent from Quality Machine Tools, which has excellent specs/finish.

Anyway, the new Shar's chucks seem to offer decent quality and some pretty tight tolerances at decent prices, the Gator/Feruda can be hit or miss but seem to work well, and I have read a few older posts where there have been an issue with the Bison chucks. I do a lot of repeat turning and currently run the Bison Set-Tru 5C, their 8" combination 4J and have been very happy with both of them, also have a Pratt Burnerd SetRite 6" chuck. The PB is also great chuck, The adjustable chucks hold a repeat TIR of better than 0.0004", the combo chuck can be zeroed in less than a minute with repeat parts. The new Shar's FS and CS might be worth considering at a lower price break, they also have their Zero-Set adjustable chucks. I also have a 4J Taiwanese independent from Quality Machine Tools, which has excellent specs/finish.