- Joined

- Apr 9, 2015

- Messages

- 32

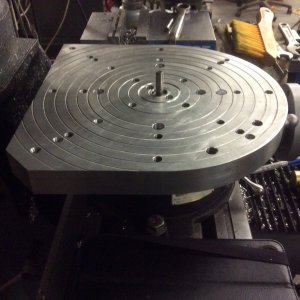

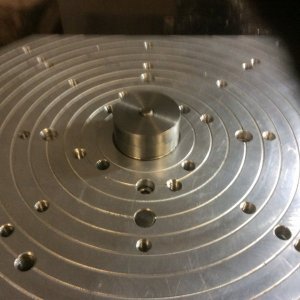

Hey everyone, I just got a new Vertex 6" rotary table for my PM-25MV yesterday and am wanting to pick up a chuck for it as well. Mostly just looking for advice on how to save money and not be disappointed.

I have been looking at chucks since I ordered the table, but wanted to wait since I wasn't sure if it was going to be 3-slot or 4-slot table because pictures and data sheets differ. The thought was that I could get a front mounted (with 4 thru bolts) 4-jaw chuck if it had 4 slots, but would need an adapter plate if it had 3 slots. Luck was on my side and it has 4 slots, so my options are a bit more open when it comes to choosing a chuck and deciding how I want to mount it.

The biggest question is, since I'm looking at a 4-jaw chuck and will need to center the work each time anyway, is there any reason to spend extra money to get a higher quality chuck? Also, any recommendations on a 4" to 6" chuck that is fairly low profile, doesn't break the bank, and has thru-bolts for mounting it?

Here is the one I have been eyeing lately...

Interstate 6" 4-Jaw Chuck - $90.02 (Picture doesn't show thru-holes but reviews say they exist)

Also, since it was hard for me to find pictures of this, here's a picture of the new Vertex 6" rotary table (Vertex HV-6) mounted along side the 4" vise that came with the PM-25MV.

I have been looking at chucks since I ordered the table, but wanted to wait since I wasn't sure if it was going to be 3-slot or 4-slot table because pictures and data sheets differ. The thought was that I could get a front mounted (with 4 thru bolts) 4-jaw chuck if it had 4 slots, but would need an adapter plate if it had 3 slots. Luck was on my side and it has 4 slots, so my options are a bit more open when it comes to choosing a chuck and deciding how I want to mount it.

The biggest question is, since I'm looking at a 4-jaw chuck and will need to center the work each time anyway, is there any reason to spend extra money to get a higher quality chuck? Also, any recommendations on a 4" to 6" chuck that is fairly low profile, doesn't break the bank, and has thru-bolts for mounting it?

Here is the one I have been eyeing lately...

Interstate 6" 4-Jaw Chuck - $90.02 (Picture doesn't show thru-holes but reviews say they exist)

Also, since it was hard for me to find pictures of this, here's a picture of the new Vertex 6" rotary table (Vertex HV-6) mounted along side the 4" vise that came with the PM-25MV.