- Joined

- Oct 28, 2016

- Messages

- 11

Hi all,

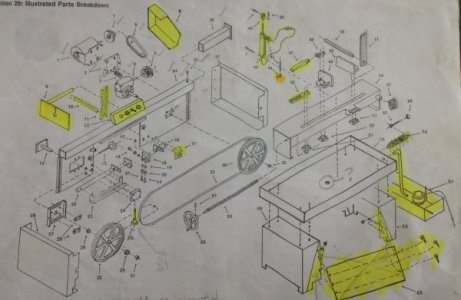

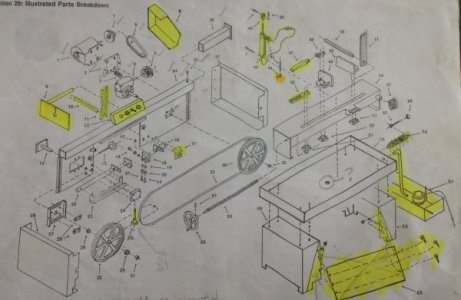

I've been working on upgrading our old Carolina HD10 band saw. I know some might say the machine is junk, but I've also heard a lot of people refer to this saw lasting them decades. I decided instead of trying to convince my boss to spend the money on a shiny new bandsaw, I'd fix up this old one-- however now I'm thinking maybe it is a piece of junk after all? I'd be really appreciative to know what you think.

I'll walk you through my process. I got a new fence on there, set up the hydraulic descent cylinder, and set up the coolant. Easy. Next I proceeded to spend hours trying to square up the blade, but I couldn't seem to get the vertical axis square at all. I tried adding an insert to the saw bed, didn't work. I tried adjusting the blade guides, which should have been straight foward-- yet still! Crooked cuts. I'm beginning to think here, the blade is sliding while cutting, it doesn't matter how I adjust the blade guide. Maybe the bearings are worn out and not holding the blade tight enough? Also at this point, I noticed the blade guide, the first one where I have attached my coolant nozzle, seems to be moving and shifting while cutting, so I pushed it back into the back panel and locked it as tight as possible so it couldn't shift, even though it's pretty far away from the site of cutting now. And still! Crooked cuts.

And now after all that, I see it, that it's not the blade that's crooked or sliding. It's the entire saw not descending straight. Like, if the saw is an arm, it's messed up in the elbow. The "elbow" is simply constructed by a pivot shaft, a longer support leg (which looks bent, no need to even measure it to make sure) and a smaller angled leg.

So my question is, do you think it's worth it replacing these parts? Would that solve my crooked cuts or be wasted time? Is this something that's worth fixing? I haven't lost hope, I know I can fab up some new parts but I'm not sure if it's a goose chase, you know? Is this a usual problem fabricators come across with horizontal band saws?

So sorry the photos all came out horizontal, I don't know how to make the upload stop that.

<-- this is the bend support leg attached to the pivot shaft

<-- this is the bend support leg attached to the pivot shaft

<--this is the angled support leg on the other side

<--this is the angled support leg on the other side

I've been working on upgrading our old Carolina HD10 band saw. I know some might say the machine is junk, but I've also heard a lot of people refer to this saw lasting them decades. I decided instead of trying to convince my boss to spend the money on a shiny new bandsaw, I'd fix up this old one-- however now I'm thinking maybe it is a piece of junk after all? I'd be really appreciative to know what you think.

I'll walk you through my process. I got a new fence on there, set up the hydraulic descent cylinder, and set up the coolant. Easy. Next I proceeded to spend hours trying to square up the blade, but I couldn't seem to get the vertical axis square at all. I tried adding an insert to the saw bed, didn't work. I tried adjusting the blade guides, which should have been straight foward-- yet still! Crooked cuts. I'm beginning to think here, the blade is sliding while cutting, it doesn't matter how I adjust the blade guide. Maybe the bearings are worn out and not holding the blade tight enough? Also at this point, I noticed the blade guide, the first one where I have attached my coolant nozzle, seems to be moving and shifting while cutting, so I pushed it back into the back panel and locked it as tight as possible so it couldn't shift, even though it's pretty far away from the site of cutting now. And still! Crooked cuts.

And now after all that, I see it, that it's not the blade that's crooked or sliding. It's the entire saw not descending straight. Like, if the saw is an arm, it's messed up in the elbow. The "elbow" is simply constructed by a pivot shaft, a longer support leg (which looks bent, no need to even measure it to make sure) and a smaller angled leg.

So my question is, do you think it's worth it replacing these parts? Would that solve my crooked cuts or be wasted time? Is this something that's worth fixing? I haven't lost hope, I know I can fab up some new parts but I'm not sure if it's a goose chase, you know? Is this a usual problem fabricators come across with horizontal band saws?

So sorry the photos all came out horizontal, I don't know how to make the upload stop that.

<-- this is the bend support leg attached to the pivot shaft

<-- this is the bend support leg attached to the pivot shaft <--this is the angled support leg on the other side

<--this is the angled support leg on the other side