- Joined

- Nov 24, 2014

- Messages

- 3,152

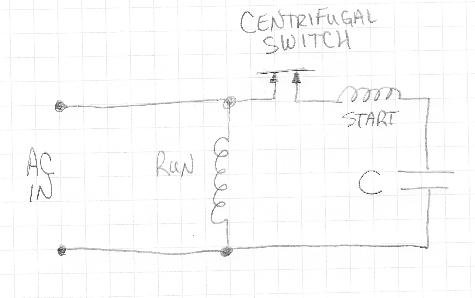

I want to temporarily reverse the rotation of an import drill press. I bought it used, so am not sure of it's country of manufacture. Probably China, maybe Taiwan, I doubt Japan. I understand that "instant reverse" isn't possible with this type of motor and that's OK. I'll power off and bring it to a dead stop before changing direction.

There is a single, metal cased, 300µF capacitor mounted to the exterior of the motor housing so I presume it's a capacitor start/induction run motor.

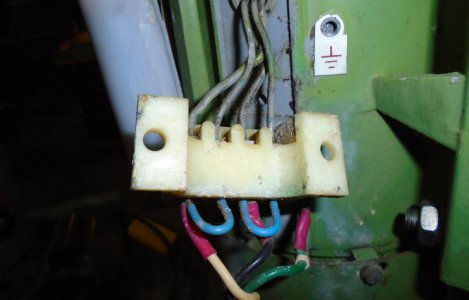

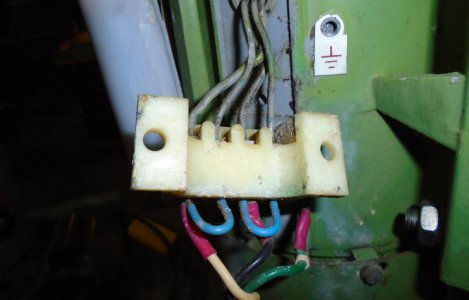

The first picture is of the back side of the terminal block (normally mounted on the outside of the motor housing). It has four circuits. The green wire is ground and disconnected from the motor housing when I took the photo. The green ground wire isn't connected to the terminal block. the black and white wires are 120 V line. The blue wires are jumpers. The four wires opposite come through a grommet from the interior of the motor.

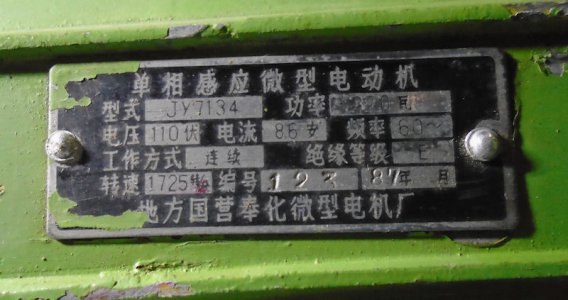

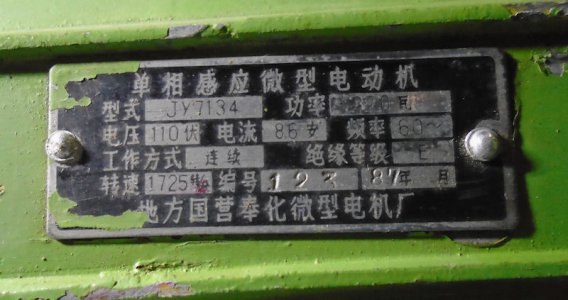

The second picture is of the motor nomenclature plate. The upper right hand box didn't photo well. The nomenclature in that box is 370 followed by a printed character (unit?).

From what I've read so far, if I reverse the start winding I'll reverse the motor rotation. It's possible, AFAIK, that two of the four wires passing through the motor housing, to the terminal block, are for run windings and two are for the start winding. Am I right about that? How can I tell (without doing damage to the motor)?

I don't want to dismount and open up the motor unless absolutely necessary. If it can be reversed by rearranging any of the wiring that you see in the picture of the terminal block, I'll probably hook up a toggle switch to accomplish FWD - REV change.

TIA

There is a single, metal cased, 300µF capacitor mounted to the exterior of the motor housing so I presume it's a capacitor start/induction run motor.

The first picture is of the back side of the terminal block (normally mounted on the outside of the motor housing). It has four circuits. The green wire is ground and disconnected from the motor housing when I took the photo. The green ground wire isn't connected to the terminal block. the black and white wires are 120 V line. The blue wires are jumpers. The four wires opposite come through a grommet from the interior of the motor.

The second picture is of the motor nomenclature plate. The upper right hand box didn't photo well. The nomenclature in that box is 370 followed by a printed character (unit?).

From what I've read so far, if I reverse the start winding I'll reverse the motor rotation. It's possible, AFAIK, that two of the four wires passing through the motor housing, to the terminal block, are for run windings and two are for the start winding. Am I right about that? How can I tell (without doing damage to the motor)?

I don't want to dismount and open up the motor unless absolutely necessary. If it can be reversed by rearranging any of the wiring that you see in the picture of the terminal block, I'll probably hook up a toggle switch to accomplish FWD - REV change.

TIA

Last edited:

Keep being cautious!

Keep being cautious!