- Joined

- Jan 1, 2014

- Messages

- 233

After posting the question of reversing my 230v mill motor almost 2 years ago using a Dayton drum switch, I knew I would be revisiting the issue again. I thanked everyone at the time for their input, but the result was always the same, one of the "line" wires was left "hot" when in the OFF position. I temporarily used a 4-way house switch in conjunction with the original ON/OFF switch to solve the issue which worked okay, but was an extra switch I had to move.

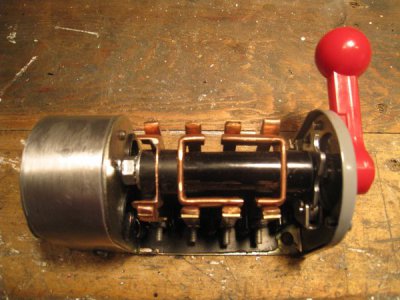

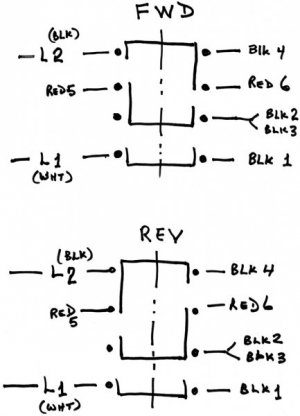

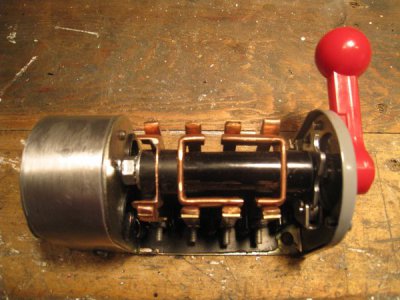

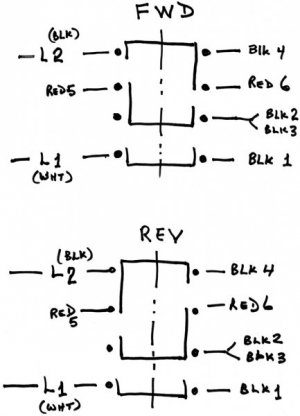

For whatever reason, I had a look at the Dayton switch again the other day, and realized that there was room for another set of contact arms on the end of the mounting bars down at the bottom, and also room on the end of the control shaft for another single row rotating contact plate. Eureka!!, this would give a way to totally cut the power in the OFF position. The existing configuration of the Dayton gives an easy way to switch the Red5 and Red6 leads for FWD and REV and to break the one "line" lead in the OFF position, now, the new contacts would give a way to break the other "line" wire in the OFF position, but also making it "hot" in either the FWD and REV position.

The Dayton moving copper parts are mounted on a non-conductive ferrule with 3/8" square shoulders and a 1/4" square bore to fit the control shaft, plus non-conductive spacers as required. To accomodate the extra contact plate on the end , I made a ferrule with a 3/8" square shoulders on both sides and 1/4" square bore, a spacer with a 3/8" square bore, a copper contact plate, and 2 brass contact arms with copper shoes riveted to them. The contact arms are .050" thick made from bolts. All the copper bits are from flattened out 1/2" copper pipe. A little milling was required on the back end of the non-conductive mounting bars to provide a flat spot to mount the new arms. Since the new arms and rotating contact plate took up some of the original space available for wires inside the box I added a small addition on the back of the Dayton to give some extra room. A total of 7 wires plus a ground from the motor wire terminal box are necessary. The sketch shows the wiring arrangement I used.

This a solution for the "live wire" problem without having to buy more expensive switches or having to use contactor blocks. Also, there are no safety issues with this mod since the new parts are as well insulated/isolated as the original switch parts.

For whatever reason, I had a look at the Dayton switch again the other day, and realized that there was room for another set of contact arms on the end of the mounting bars down at the bottom, and also room on the end of the control shaft for another single row rotating contact plate. Eureka!!, this would give a way to totally cut the power in the OFF position. The existing configuration of the Dayton gives an easy way to switch the Red5 and Red6 leads for FWD and REV and to break the one "line" lead in the OFF position, now, the new contacts would give a way to break the other "line" wire in the OFF position, but also making it "hot" in either the FWD and REV position.

The Dayton moving copper parts are mounted on a non-conductive ferrule with 3/8" square shoulders and a 1/4" square bore to fit the control shaft, plus non-conductive spacers as required. To accomodate the extra contact plate on the end , I made a ferrule with a 3/8" square shoulders on both sides and 1/4" square bore, a spacer with a 3/8" square bore, a copper contact plate, and 2 brass contact arms with copper shoes riveted to them. The contact arms are .050" thick made from bolts. All the copper bits are from flattened out 1/2" copper pipe. A little milling was required on the back end of the non-conductive mounting bars to provide a flat spot to mount the new arms. Since the new arms and rotating contact plate took up some of the original space available for wires inside the box I added a small addition on the back of the Dayton to give some extra room. A total of 7 wires plus a ground from the motor wire terminal box are necessary. The sketch shows the wiring arrangement I used.

This a solution for the "live wire" problem without having to buy more expensive switches or having to use contactor blocks. Also, there are no safety issues with this mod since the new parts are as well insulated/isolated as the original switch parts.