- Joined

- Nov 21, 2015

- Messages

- 226

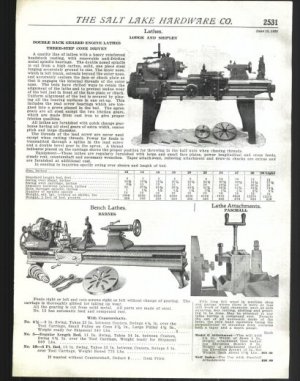

Guys, thanks for the input, and keep it coming. I agree, it does NOT look abused. However, the pictures are poor, and are from the seller. It was his brother-in-law's lathe, and his sister wants it out of the basement. That is the seller's advertised price, not one that I set. If the old girl is even prettier in person, I will buy it. When I get it home, the disassemble, clean, and re-assemble, then calibrate/adjust process begins. This country made it through WWI and WWII using these, and I expect that if this hasn't been abused, it will be a good "big job" lathe for my purposes. I like doing things "the old way" and with older machinery, so this might fit right in! Lastly, as an added bonus, I have that disease where I love to take old things and make them work again. THEN USE THEM! LOL. We will see what the on-site visit discovers.