-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can 220 VAC 1-Phase motor be wired to run 2-speed?

- Thread starter Big Bob

- Start date

- Joined

- Jan 28, 2011

- Messages

- 3,484

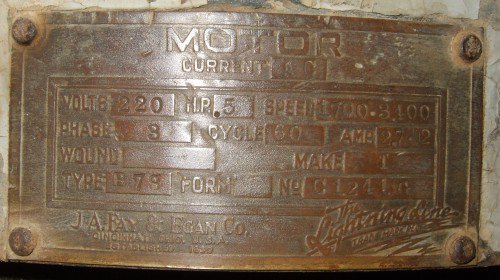

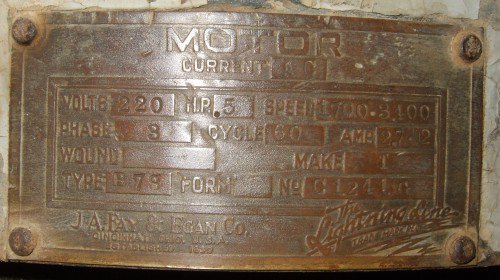

You have to look at the motor tag. It will show whether or not you can have 2 speeds. Here is a sample motor tag from a 3 phase motor.

Once you confirm that it can do it, you will have to rewire via switch box to give you Hi and Low. You should find a motor shop to help you with this as it will be tough to do without some experience.

Pierre

Once you confirm that it can do it, you will have to rewire via switch box to give you Hi and Low. You should find a motor shop to help you with this as it will be tough to do without some experience.

Pierre

- Joined

- Nov 16, 2012

- Messages

- 5,596

The motor must be designed to run at 2 speeds. Most are not 2 speed. Info on the motor-plate will tell you. I assume your service power is single phase 220. If your switch-box was made for 3 phase, it's unlikely it can be reused for single phase.

Sounds like you're converting a 3-phase machine to single phase. You might consider keeping the 3-Phase motor and using a VFD to convert single phase to 3-phase. If you go that route, you should not put a switch in between the VFD and motor as it will burn-up the VFD in time.

Tell us more about what you're up to and maybe there's a solution.

Also, if you're not familiar with motor wiring, try to find someone with knowledge to watch over your shoulder. -Might spare you from burning-up a motor or shocking yourself.

Sounds like you're converting a 3-phase machine to single phase. You might consider keeping the 3-Phase motor and using a VFD to convert single phase to 3-phase. If you go that route, you should not put a switch in between the VFD and motor as it will burn-up the VFD in time.

Tell us more about what you're up to and maybe there's a solution.

Also, if you're not familiar with motor wiring, try to find someone with knowledge to watch over your shoulder. -Might spare you from burning-up a motor or shocking yourself.

- Joined

- Dec 23, 2012

- Messages

- 770

It has to be 2 speed for 1 phase

They do make them I put one on my mill

Dave

They do make them I put one on my mill

Dave

I have MK1.5 Colchester that has control box for 2 speed. manual schematic is 3- phase.

Motor is 3 horsepower Brooke Compton.

I don'tknow much about motors how to wire if possible vs 3 phase schematic.

Anybody know?

Bob

- Joined

- Sep 11, 2012

- Messages

- 329

Motor speed in a AC motor is really simple. 2 pole-3600rpm. 4 pole-1800rpm. 6 pole 900rpm. A two speed motor is not magic. It is simply one stator with two complete sets of windings. Like two motors in one. Speed is dependant on cycles or hertz, in our case 60. Motors stating small reductions in rpm such as 1750 are accounting for such things a bearing friction and motor slip. The poorer the power factor the more the slip, the more the slip the slower it runs, hotter it gets and less effecient it operates. Pretty simple.

50 cycle motors such as most parts of the world work a a slower pace. But then so usually do the people!!

50 cycle motors such as most parts of the world work a a slower pace. But then so usually do the people!!