- Joined

- Jun 17, 2011

- Messages

- 2,069

Okay, guys. A couple of months ago, I mentioned a Project-in-Waiting that I called a Camjack Knurler. When you invent something, you're allowed to make up words, too. It came about because I had checked out several sites on clamp knurlers. Most seem to use a 6 mm threaded shaft to apply pressure, but some commented that it didn't have enough force for steel. This tool has plenty of pressure, easily controlled.

Members of this forum may use this principle to build their own, but, of course, may not profit from my design.

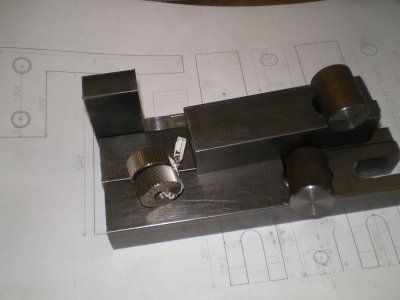

Here's a look at the finished product in use, mounted in the QCTP. The bar on the top with the 1/4" jack screw is the camjack. When the tail is raised with the jack screw, the camjack pivots around the opposite end and pulls up on the 1/2"-20 main screw. It provides more than 5 to 1 mechanical advantage. The knurl arms are pivoted farther away from the roller ends than normal. This unit is designed for up to 2" knurled work.

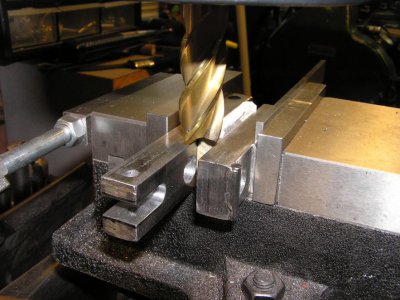

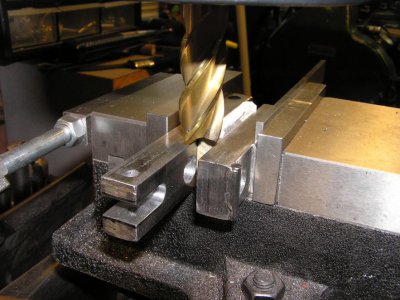

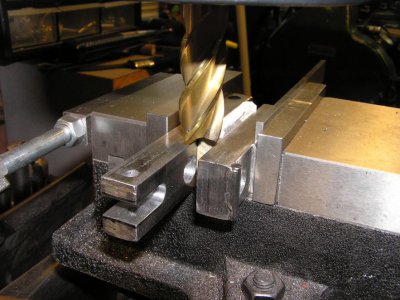

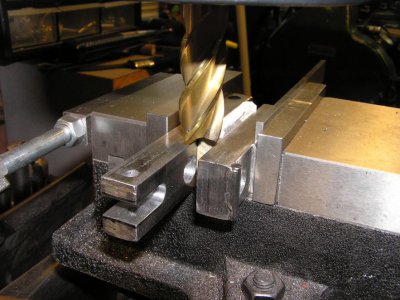

Jumping back to some of the construction details. The bottom bar and the camjack are clamped in the vise with a piece of 3/8" aluminum between them to plunge-mill the depressions for the 3/4" main screw pivot blocks.

The axles for the knurls were turned from a pair of 5/16" grade 8 bolts.

The complete tool is set up for the test cut. The 1/2"-20 main screw works well with a lug nut as the adjusted. This is turned hand-tight once the crossfeed is centered on the work, with the camjack all the way down. Then the jackscrew is tightened with the work oiled and the lathe running at knurling speed. Enough pressure can be applied by hand that I may just add a knurled top on the jackscrew.

I'm quite pleased with the way it works. This will, of course, be the main screw nut. It has to have a knurled one, doesn't it? (See the top photo.)

Members of this forum may use this principle to build their own, but, of course, may not profit from my design.

Here's a look at the finished product in use, mounted in the QCTP. The bar on the top with the 1/4" jack screw is the camjack. When the tail is raised with the jack screw, the camjack pivots around the opposite end and pulls up on the 1/2"-20 main screw. It provides more than 5 to 1 mechanical advantage. The knurl arms are pivoted farther away from the roller ends than normal. This unit is designed for up to 2" knurled work.

Jumping back to some of the construction details. The bottom bar and the camjack are clamped in the vise with a piece of 3/8" aluminum between them to plunge-mill the depressions for the 3/4" main screw pivot blocks.

The axles for the knurls were turned from a pair of 5/16" grade 8 bolts.

The complete tool is set up for the test cut. The 1/2"-20 main screw works well with a lug nut as the adjusted. This is turned hand-tight once the crossfeed is centered on the work, with the camjack all the way down. Then the jackscrew is tightened with the work oiled and the lathe running at knurling speed. Enough pressure can be applied by hand that I may just add a knurled top on the jackscrew.

I'm quite pleased with the way it works. This will, of course, be the main screw nut. It has to have a knurled one, doesn't it? (See the top photo.)