- Joined

- Aug 21, 2016

- Messages

- 171

Gentlemen, my beautiful wife got me for Christmas a much needed parting blade and holder for my lathe which is equipped with a BXA/200 series toolpost.

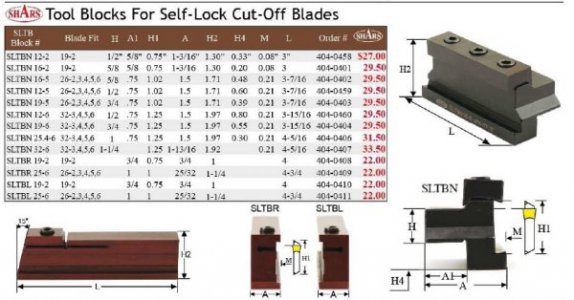

She got me a Dorian SGIH 26-4 Blade and a Dorian QITP30N-7-71C holder with a few inserts. Well the Dorian holder only accepts the 3/4" SGIH19 series blades. I'd really like to keep the taller blade for rigidity sake, but it seems Dorian doesn't make one for the taller 1" blades.

Aloris makes the #77 holder which appears to be correct. I there any other alternatives? I like the more secure mounting the Dorian clamp has vs the Aloris axial wedge clamp. Maybe I shouldn't worry about that.

I really wish tooling was easier to comprehend and deal with. There's so much out there and conflicting info, not enough info, bad info, no cross-over info, etc etc.

She got me a Dorian SGIH 26-4 Blade and a Dorian QITP30N-7-71C holder with a few inserts. Well the Dorian holder only accepts the 3/4" SGIH19 series blades. I'd really like to keep the taller blade for rigidity sake, but it seems Dorian doesn't make one for the taller 1" blades.

Aloris makes the #77 holder which appears to be correct. I there any other alternatives? I like the more secure mounting the Dorian clamp has vs the Aloris axial wedge clamp. Maybe I shouldn't worry about that.

I really wish tooling was easier to comprehend and deal with. There's so much out there and conflicting info, not enough info, bad info, no cross-over info, etc etc.

Last edited: