- Joined

- Jan 12, 2017

- Messages

- 19

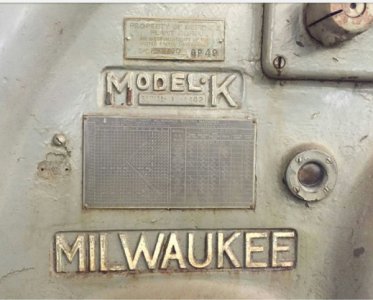

Hi I just bought my first lathe and year ago and now want a mill. I only buy vintage machines because I have a thing for older stuff. I found a millwaukee model k for a good priced and alot of tools. Can anyone give me a idea is this a good make/model and what I need to look for when go look at it?