- Joined

- Nov 25, 2016

- Messages

- 175

Hello all,

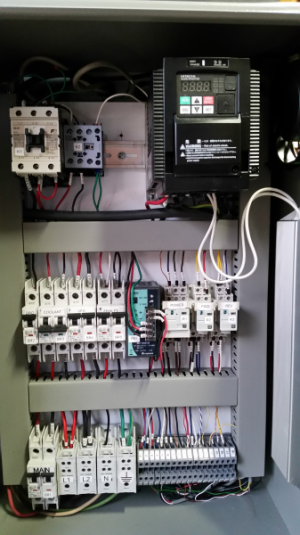

Embarrassingly trivial question... is there a preferred approach in attaching the organs (VFD, contactors, etc) of an enclosure to the mounting plate? Drill/tap or through-bolt? Thanks in advance.

CW

Embarrassingly trivial question... is there a preferred approach in attaching the organs (VFD, contactors, etc) of an enclosure to the mounting plate? Drill/tap or through-bolt? Thanks in advance.

CW