-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building A Tool Post Grinder

- Thread starter Mark_f

- Start date

This is good to know. I will be putting a pretty aluminum housing over the motor so if needed , I can put a little computer fan in the end of the motor housing. But I don't think It will run long enough at a time to worry about it.your treadmill motor will get pretty hot without any forced air cooling. I ran my 1hp one for a while without a fan and it got too hot to touch after an hours use. Then again, you might not be using it for long enough stretches for it to matter.

oh, and beautiful spindle too!

LOL.... I'm old.... I wanted one I could lift. Plus , I cant see hanging something that weighs half as much as my lathe on the tool post. It just don't seem right. I will remove the compound and the grinder will mount directly on the saddle. there will be height adjustment and it will swivel to an angle. Watch...I think you will like it.Nice design, Mark. I like the compact nature of it. Brilliant idea to use/modify an existing spindle.

I have a design I've been working on for a long time. When I can, I'll execute it and post as a project. I am pretty sure mine will outweigh yours a good bit lol.

Tony.... I will be testing the bender soon for capacity. I'll let you know.

It is an oil fill hole. the spindle is filled 1/3 with high grade turbine oil to lube the bearings. The plug has a .031" hole in it for a vent to keep pressure from building in the spindle. With out the vent oil will get pushed out passed the oil seals.I have to ask

What is the brass plug in the spindle housing for?

Ray

- Joined

- Jan 22, 2011

- Messages

- 8,031

Well, I hear you on hefting the thing, but my smallest lathe is a 17" swing, so I think I should make it size appropriate.

F

f350ca

Forum Guest

Register Today

Nice build Mark. I don't use my tool post grinder often, but when I do I use it on the compound, and have it swung 5.7 degrees from the spindle axis. 0.001 on the compound gives 0.0001 in feed.

Greg

Greg

I chose to take the compound off for a couple of reasons. I figure the setup is more solid. The more you stack the more things flex. .001 feed on the saddle will do the same. The compound is easy to remove ( loosen two set screws and lift off is just as easy as removing the tool post). Doing this gives me more room than mounting on the compound. With the compound, there is only about 1 1/2" to spindle center. It is hard to keep the unit that thin. Without the compound, there is about 2 5/8" to spindle center.Nice build Mark. I don't use my tool post grinder often, but when I do I use it on the compound, and have it swung 5.7 degrees from the spindle axis. 0.001 on the compound gives 0.0001 in feed.

Greg

I do have one question though. I read in Dumore's instructions that the grinder turns CCW ( looking at the stone)or grinds downward. The spindle should rotate the other direction, but that is not a good idea with a screw on chuck. Does it really matter that much? I could reverse the grinder but it would throw the Sparks up instead of down. That was for external grinding , but for internal grinding , they say to run them the same direction. I don't understand why.

F

f350ca

Forum Guest

Register Today

Been a while since I had it out of its box but I think your correct Mark, it runs CCW. I can't see the direction of part rotation making a lot of difference. The surface speed of the wheel is so much higher than the material movement. It would be akin to climb milling verses conventional. At the same time the amount of force the wheel puts on the part is pretty small, can't see it ever backing a chuck off. As a last example, the work moves both directions in relation to the wheel when your surface grinding. I've never had the opportunity to use one but would guess the finish is the same in either stroke.

Greg

Greg

- Joined

- Sep 28, 2013

- Messages

- 4,302

This is good to know. I will be putting a pretty aluminum housing over the motor so if needed , I can put a little computer fan in the end of the motor housing. But I don't think It will run long enough at a time to worry about it.

it might well be fine, especially if you use a little bit of heat transfer compound between the motor and that large alu plate that's holding it. If not, any small fan would do fine. A user called Dickeybird on one of the other sites shrunk a PET bottle around the end of his and a fan, looked pretty pro

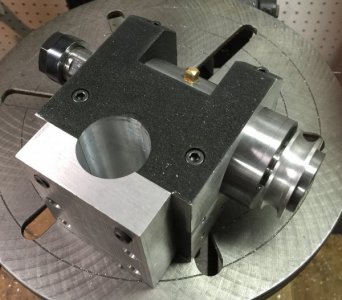

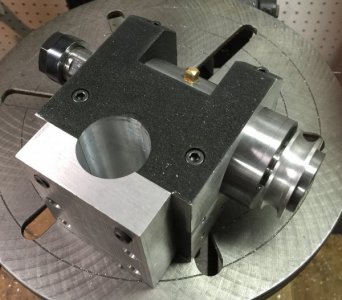

I reamed a .750 hole in the grinder base to fit a post. Then painted the unit and today was going to make the mount for the lathe. Although a 3/4" post would have been sturdy enough, I wasn't happy with it .... Sooooo.... I made a couple changes.

I scabbed a 1" thick block to the back of the base and bored a 1 1/2" diameter hole for a nice big fat post. This post will have the "dovetail" on the bottom to fit the South Bend saddle. I cut .010" off the left side of the block so when the left three bolts are tightened, it provides a solid pinch lock on the post.there will also be a height adjuster similar to a QCTP . But more about that later. Next thing is to finish the mount for the lathe. ( I'm much happier with this setup)

I scabbed a 1" thick block to the back of the base and bored a 1 1/2" diameter hole for a nice big fat post. This post will have the "dovetail" on the bottom to fit the South Bend saddle. I cut .010" off the left side of the block so when the left three bolts are tightened, it provides a solid pinch lock on the post.there will also be a height adjuster similar to a QCTP . But more about that later. Next thing is to finish the mount for the lathe. ( I'm much happier with this setup)