Thank you. I'm doing well but still dealing with the mini strokes. I guess they are a crapshoot. It either happens or it doesn't. The docs are watching and doing everything they can think of to prevent a major problem.Mark I'm so happy for you and glad to see your jumping right into an awesome build.

Thank you GOD for answering our prayers for Mark AMEN. I'm looking forward to this they are Kool.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a Pulse EDM machine

- Thread starter Mark_f

- Start date

- Joined

- Jan 26, 2015

- Messages

- 1,939

Mark,

If you need any decals for your panel I have some vinyl decal paper and can print them up for you. Just need a drawing with sizes. These are water slide decals with a white background. Or I have regular clear water slide decal paper.I

If you need any decals for your panel I have some vinyl decal paper and can print them up for you. Just need a drawing with sizes. These are water slide decals with a white background. Or I have regular clear water slide decal paper.I

Thank you Bill. The control font panel is being engraved at a local engraving shop. But I will be looking for lettering for the head of the machine. I will let you know when I get that far.Mark,

If you need any decals for your panel I have some vinyl decal paper and can print them up for you. Just need a drawing with sizes. These are water slide decals with a white background. Or I have regular clear water slide decal paper.I

Thanks.

- Joined

- May 4, 2015

- Messages

- 3,583

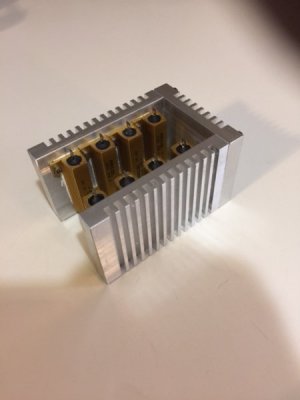

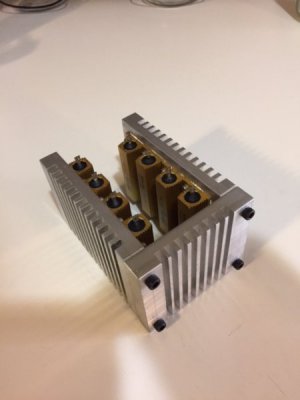

Would some holes drilled thru the fin bottoms let more air circulation for cooling. Just wondering ?I did some research with the manufacturer of the resistors and decided to change the setup to be more efficient. I made these heat sinks from some aluminum bar stock. They should work adequately with the fan blowing over them.

View attachment 226731 View attachment 226732

Actually.... no. The surface area of the heat sink dissipates the heat ... thus the fins , to increase surface area. The air bowing through the heat sink will help carry the heat out. I use a high grade thermal compound between the resister and the heat sink to aid heat transfer.Would some holes drilled thru the fin bottoms let more air circulation for cooling. Just wondering ?