- Joined

- Nov 25, 2015

- Messages

- 8,389

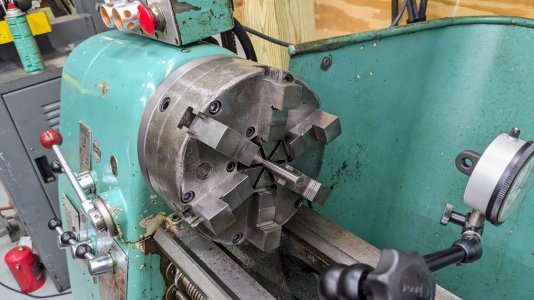

perimeter of the cavity. most will be flung by centrifugal force.When you say "outside" you just mean to the outside perimeter of the cavity inside the chuck? Or do you mean that they actually would exit the chuck somehow?