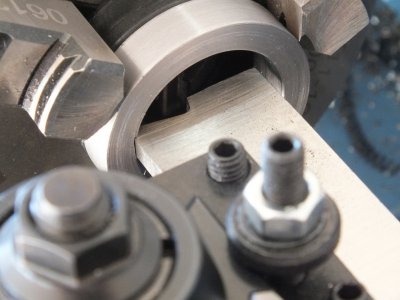

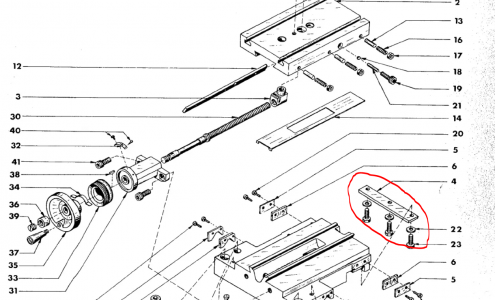

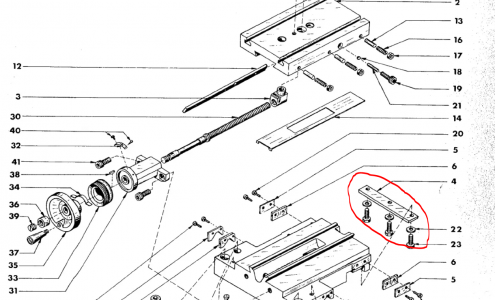

I am thinking about trying it out and the only thing I worry about is whether any harm will be done to the lathe. The cross slide is designed to withstand forces pushing it downward but when broaching is done, the reaction of the cutting force will tilt the side of the slide closer to the chuck upward. On the back side of the cross side, it's just a piece of plastic ( circled in red below ) that keeps it from being lifted up. Can anyone share your thoughts ?

Last edited: