Now that I am getting close on the X axis power feed install I started thinking about what else would be "nice to haves". I'm looking for suggestions/ideas based on a hobbiest shop and a guy who doesn't use a Bridgeport 8 hours a day and 5 days a week. Following are the things I am considering (in the order I think they would be the best bang for the buck). The blank spots are indication that I currently think the last two would not be a good investment. Feel free to add improvements I have not thought about or to change the order.

1. 2 axis (X and Y) DRO

2. Y axis power feed

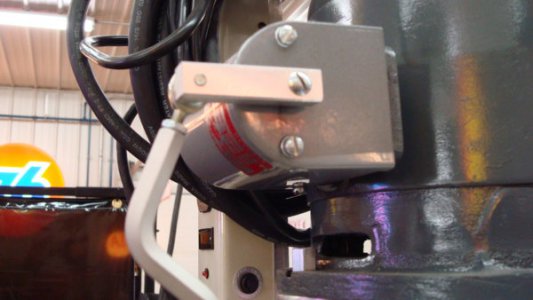

3, More convenient control box location

4,

5,

6,

7. One shot oiler

8. Z axis power feed

Thanks for your thoughts

Rick

1. 2 axis (X and Y) DRO

2. Y axis power feed

3, More convenient control box location

4,

5,

6,

7. One shot oiler

8. Z axis power feed

Thanks for your thoughts

Rick