- Joined

- Jul 20, 2014

- Messages

- 1,386

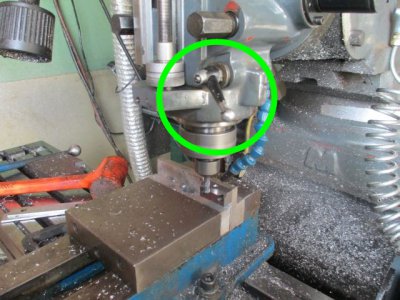

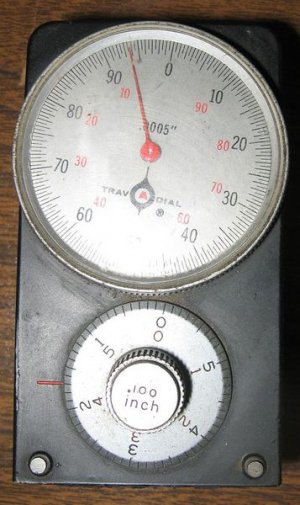

Used the mic dials on the BP mill today for the first time.

Worked really well. I used my Starrett 827B edge finder

and was able to locate my holes right on the spot that I

marked off and punched. I really want an Accurite II. Working with the mill

would be a breeze! How much for the complete Accurite set up?

I know theres a lot of hardware to go with the electronics. Is it a lot of work

to install and what kind of tools would I need?

Thanks

Worked really well. I used my Starrett 827B edge finder

and was able to locate my holes right on the spot that I

marked off and punched. I really want an Accurite II. Working with the mill

would be a breeze! How much for the complete Accurite set up?

I know theres a lot of hardware to go with the electronics. Is it a lot of work

to install and what kind of tools would I need?

Thanks