-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BP 2J Rebuild

- Thread starter sd624

- Start date

- Joined

- Dec 15, 2012

- Messages

- 150

- Joined

- Dec 15, 2012

- Messages

- 150

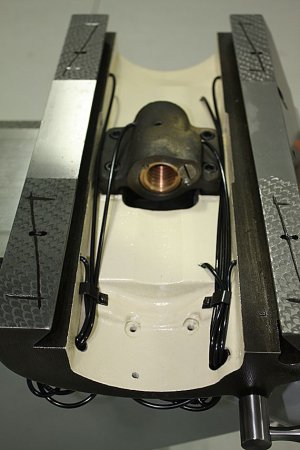

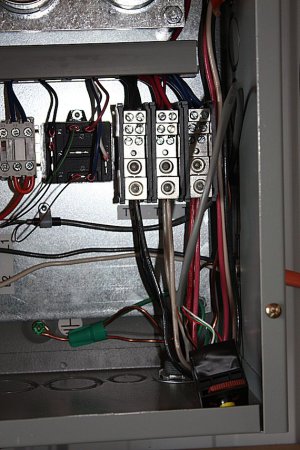

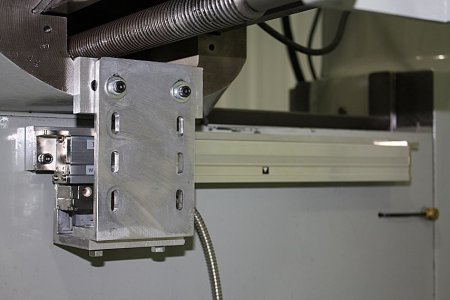

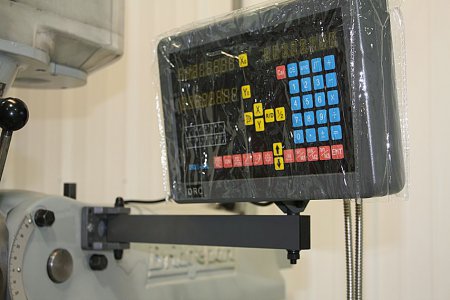

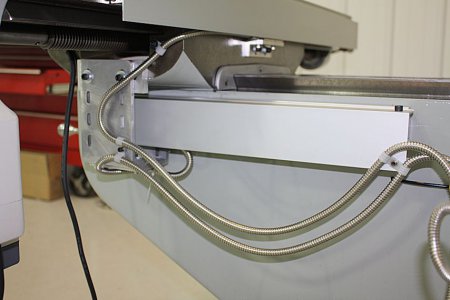

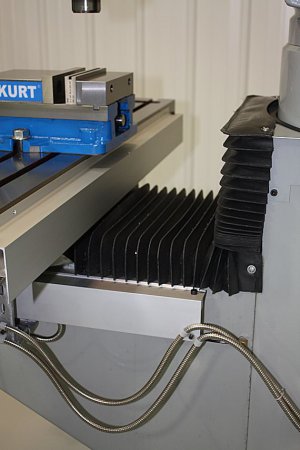

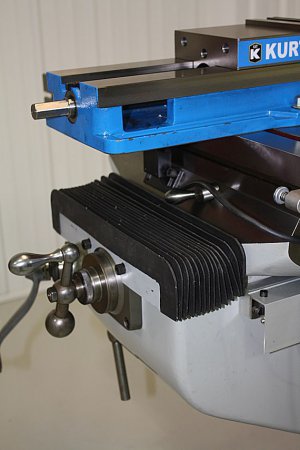

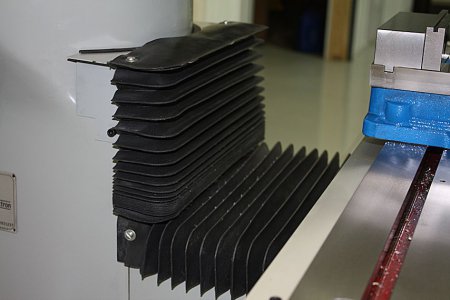

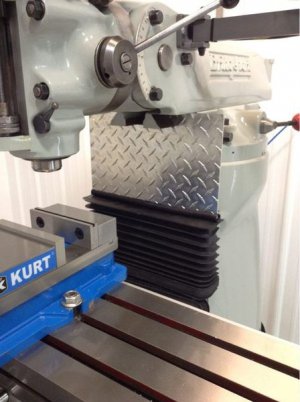

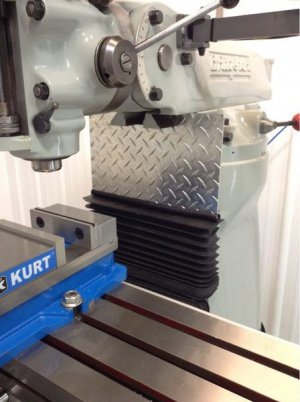

Just to summarize the machine has been completely taken apart, cleaned, inspected, and any part that was wore or out of spec was replaced. The spindle was sent out for rebuild (3 new bearings and a taper regrind). The table, saddle, knee, gibs and column were sent out for regrinding, scrapping, fitting, and reflaking. All metal parts (table locks, handles, and ect) were cleaned and polished. The one shot oiling system was rebuilt. All new metering jets, new plastic lines, and fittings. Spindle bushings replaced. New drive and timing belt. Gear housing assy completely rebuild. New bearing on the motor. Basically any that that could be done was done.

I hope you guys enjoy the pics and it wasn't to much!!!!

I hope you guys enjoy the pics and it wasn't to much!!!!

Last edited:

- Joined

- Apr 12, 2011

- Messages

- 3,472

WOW!

That is amazing you did all that on a hobby machine. You have one sweet machine. Looks like you thought of everything. Not only the resto but the add-ons. Now the real fun begins, getting it dirty. I bet you had quite the learning experience.

That is amazing you did all that on a hobby machine. You have one sweet machine. Looks like you thought of everything. Not only the resto but the add-ons. Now the real fun begins, getting it dirty. I bet you had quite the learning experience.

Last edited:

- Joined

- Jun 22, 2012

- Messages

- 1,552

Man this thing looks amazing, better than new. I was really liking the mill rite in the back ground, I tried to buy one but the deal never happened. I wish I had the room for a bridgy, yours came out great. I'm glad I found this thread, it was a very educational and fun read. Thanks for doing this.

Greg

Greg