A

Alan H.

Forum Guest

Register Today

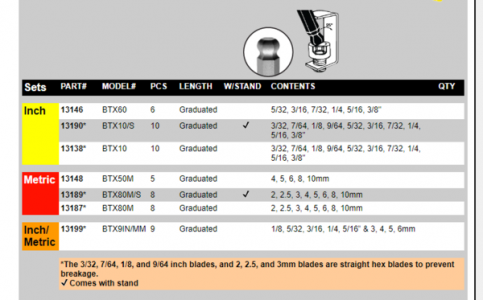

I am going to upgrade my hex T handles. From my research here and elsewhere, Bondhus is what I have settled on. I will buy two sets, metric and SAE. They have lots of options to choose from.

So now to decide:

Feedback and/or advice would be appreciated.

So now to decide:

- Ball or hex end? (Leaning to plain hex end for strength - got other ball ends when needed.)

- Lengths - graduated, 6", or 9"? (EDIT: Ball ends only come in graduated sets)

- Set with stand or without? Are their stands worth having? To buy a set with a stand is likely the answer since they will be more available and therefore cheaper.

Feedback and/or advice would be appreciated.

Last edited by a moderator: