- Joined

- Aug 5, 2013

- Messages

- 125

So I have a BMW G650X Challenge that I really enjoy, but hate giving Hans and Franz more money for parts that were not made correctly to begin with. What happens on this bike is the clutch throwout uses the clutch cover as a linear slide bearing to actuate the clutch control mechanism.

Over time, the steel part wears the die cast aluminum cover bore and the clutch then does not disengage properly. The solution from BMW is to buy $400 worth of parts. Or use my tools to put a bronze bushing in the clutch cover and fart in the general direction of BMW.

After getting the parts of the bike, you need to get two bearings out of the cover prior to machining. The 12mm ID bearing at the top is easy to use a bearing puller. The 8mm bearing requires you to make a puller. For this I used an 8mm allen head and repurposed motorcycle chain pin:

Got the little bearing out, but did damage it a bit:

Ebay bearing replacement was $5.

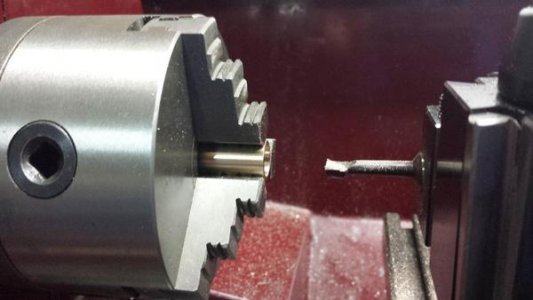

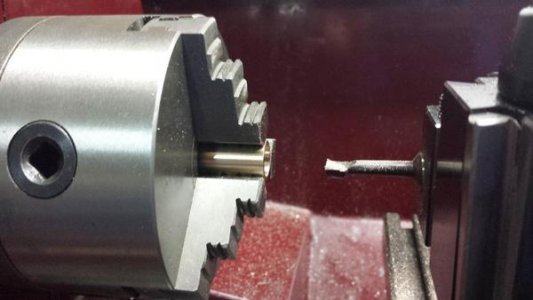

Getting set up to make the bore cut to sleeve my clutch cover:

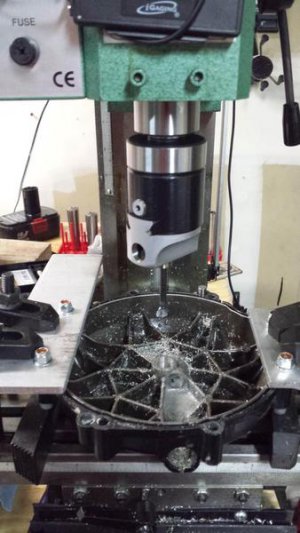

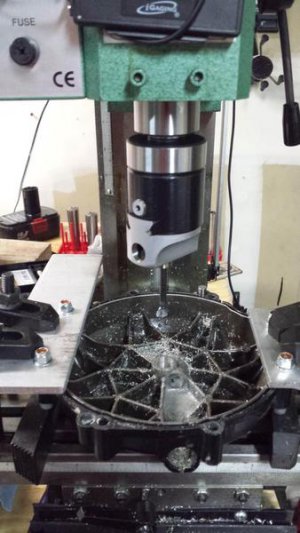

Boring out the bronze bushing to the correct ID:

I forgot to take photos of the milling of the side of the bushing. Used a ½" end mill to make the slot for the shaft pass thru.

So back to the boring. After taking ~0.030" out of the bore, you can start to see how worn it was.

A pile of chips later, the bore is about 0.001" undersize for the bushing OD.

Now to fit the finished bushing into the hole and get the slot to line up. Put the bushing in the freezer for 20 minutes:

Clean off the clutch cover and get the chips and residual oil off it. Then boil some water in a frying pan:

Begin cooking your cover:

Check the temperature:

When it nears 100C, pull it out, drop the water out of the bushing hole, then grab the bushing from the freezer and place it. It drops right in with a little push (through the oven mitt) and a quick glance to make sure I lined it up adequately.

The repeat the hot water + freeze trick to install the 8mm bearing and 12mm bearing. Reassemble:

Then come to a hard stop for the evening when the E-clip that goes at the top of the shaft decided to go on vacation somewhere in the shop.....

Over time, the steel part wears the die cast aluminum cover bore and the clutch then does not disengage properly. The solution from BMW is to buy $400 worth of parts. Or use my tools to put a bronze bushing in the clutch cover and fart in the general direction of BMW.

After getting the parts of the bike, you need to get two bearings out of the cover prior to machining. The 12mm ID bearing at the top is easy to use a bearing puller. The 8mm bearing requires you to make a puller. For this I used an 8mm allen head and repurposed motorcycle chain pin:

Got the little bearing out, but did damage it a bit:

Ebay bearing replacement was $5.

Getting set up to make the bore cut to sleeve my clutch cover:

Boring out the bronze bushing to the correct ID:

I forgot to take photos of the milling of the side of the bushing. Used a ½" end mill to make the slot for the shaft pass thru.

So back to the boring. After taking ~0.030" out of the bore, you can start to see how worn it was.

A pile of chips later, the bore is about 0.001" undersize for the bushing OD.

Now to fit the finished bushing into the hole and get the slot to line up. Put the bushing in the freezer for 20 minutes:

Clean off the clutch cover and get the chips and residual oil off it. Then boil some water in a frying pan:

Begin cooking your cover:

Check the temperature:

When it nears 100C, pull it out, drop the water out of the bushing hole, then grab the bushing from the freezer and place it. It drops right in with a little push (through the oven mitt) and a quick glance to make sure I lined it up adequately.

The repeat the hot water + freeze trick to install the 8mm bearing and 12mm bearing. Reassemble:

Then come to a hard stop for the evening when the E-clip that goes at the top of the shaft decided to go on vacation somewhere in the shop.....