- Joined

- Mar 21, 2013

- Messages

- 4,063

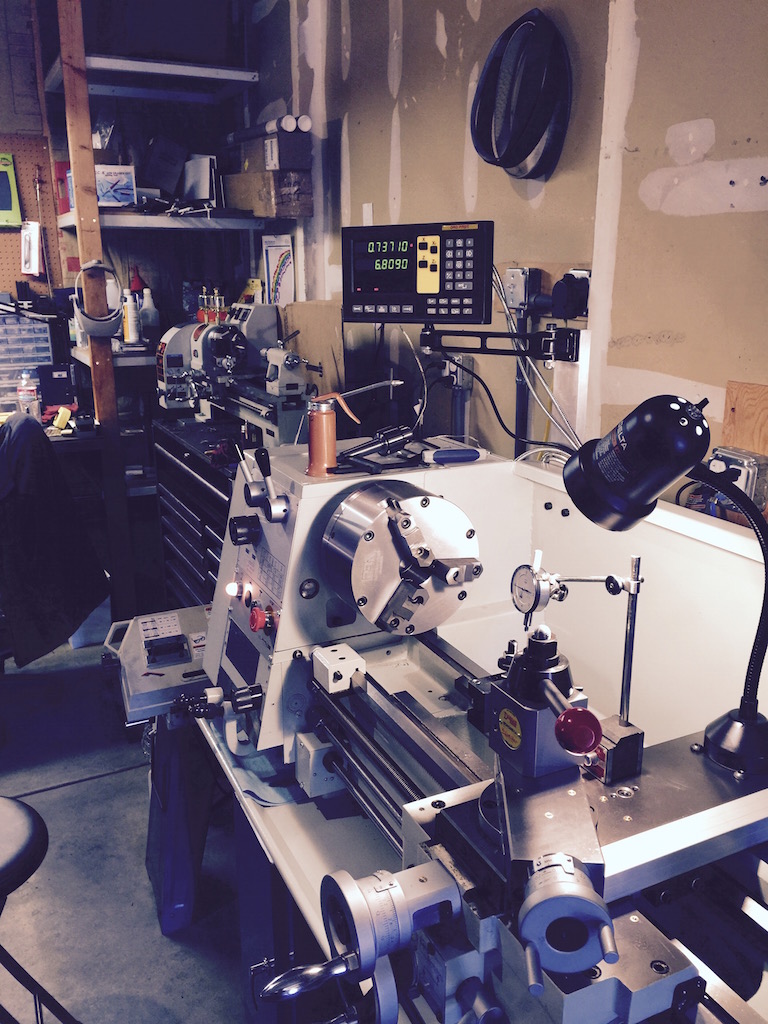

Well I managed to get everything installed that I wanted and things are looking pretty good. I mounted the backing plate for the Pratt and I'll be dammed if I can find more than a tenth or two (the new Mitsu .0001 DI is kinda twitchy) in any position on the spindle. So I didn't skim it and just mounted the chuck on it. Oh and for you folks thinking about a Pratt: I had the chuck face down on the bench and trying to get the backing plate to slide into the 'pocket' on the back of the chuck but any tilt of the backing plate will have it wedge in there pretty tight. There is only about 2-3 thou difference between the raised area of the backing plate and the recess in the back of the chuck. I'll bet this chuck doesn't need half that to zero out a part.

Had it spinning at the highest speed in low range, about 800 rpm, and I found myself standing back by the tailstock. I spin a 5" on the little SB at over 2000 rpm, but I can't imagine this thing ever spinning that fast. I'll be in the other room if it does. Big Chuck...

I made a little shield for the read head on the Z axis to keep the larger fodder at bay. Sorry Coolidge, I wasn't up for relocating that 40" scale. And I got my Dorian mounted! Now I just need my 5/8" indexable set to get here from Shars and I can start cutting stuff.

I have a 1.25"x20" piece of TGP I was going to stick in the chuck and run a DI down it's length to see if the headstock is true. I also have a 2"x12" piece of aluminum that I could use. Not sure which would be better so maybe I'll try both.

Dinner's ready so here's some eye candy:

She's a little bigger than the little SB.

Had it spinning at the highest speed in low range, about 800 rpm, and I found myself standing back by the tailstock. I spin a 5" on the little SB at over 2000 rpm, but I can't imagine this thing ever spinning that fast. I'll be in the other room if it does. Big Chuck...

I made a little shield for the read head on the Z axis to keep the larger fodder at bay. Sorry Coolidge, I wasn't up for relocating that 40" scale. And I got my Dorian mounted! Now I just need my 5/8" indexable set to get here from Shars and I can start cutting stuff.

I have a 1.25"x20" piece of TGP I was going to stick in the chuck and run a DI down it's length to see if the headstock is true. I also have a 2"x12" piece of aluminum that I could use. Not sure which would be better so maybe I'll try both.

Dinner's ready so here's some eye candy:

She's a little bigger than the little SB.