HMAN, Really clever with the casters. Can you show a few more pics?

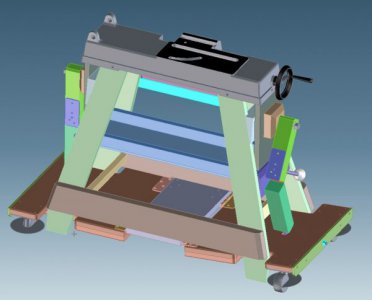

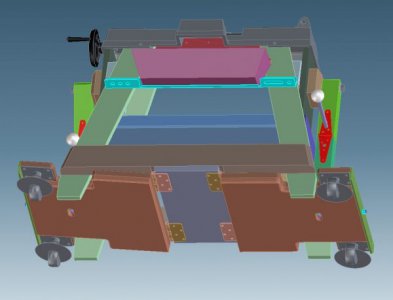

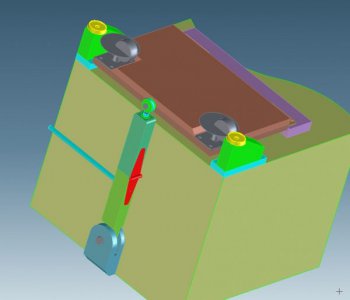

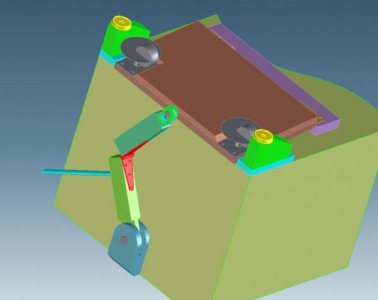

OK. Here are a few, plus some CAD screen shots. As you can see, lots of configurations are possible. I've even gone so far as to weld up a pair of caster plates to go

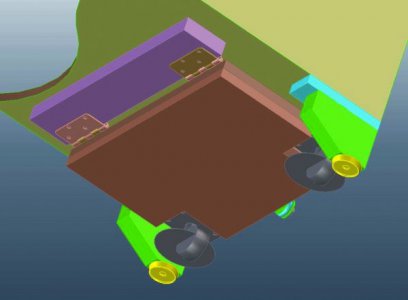

around the legs of the green bandsaw frame shown in the first photo. All the others I've done have used a double thickness of ¾" plywood for the caster plate. Weight capacity of the lift is probably a maximum of around 500 lbs. (250 per caster plate) if made of wood. My table saw weighs in at 350 lbs, and it's pretty easy to raise and lower.

A couple things I've found to be important: 1. Be sure the casters clear the feet and other features of the machine. The "halos" around the casters in the CAD screen shots represent the full rotation space of the casters. 2. Be sure the plate the casters are mounted on is stiff. You don't want it to tilt or flex under load. I space the hinges as far apart as possible. My go-to caster plate is a double thickness of ¾" plywood. I'll cut the lower plate away around the casters, to reduce overall height. 3. The knee pivots on a good, strong bolt at the top. I usually use ½". 4. There are several ways to orient the lifting bar. I've tried several over the years (as shown in various photos). Experience has shown that the

best place is on the upper knee section, on the same side as the hinge. 5. You can get increased leverge by making the upper section of the knee shorter than the lower. 6. The knee itself is 3 thicknesses of ¾" plywood glued together. The mating surfaces of the knee sections should be flat and square. When the tool is raised onto the casters, it's these surfaces that keep the knee upright. 7. The joint between the bottom of knee and the pivot pin on the caster plate needs to "flex" in two directions. My simple joint consists of an eyebolt inserted in the bottom of the knee and a stack of washers (or short length of pipe) between fender washers on a pin (⅜" handy rod or bolt) that extends out of the caster plate. 8. Final adjustment of the knee length is provided by epoxying a nut inside the knee. This allows the eyebolt to be run in or out as needed. 9. Be sure the pivot pin is securely anchored on the caster plate. If the caster plate is wood, I'll face it with a piece of steel bar to keep the wood from splitting under load.

Kgill & larry4406, your request for photos (and info) is very timely. I'm currently in the process of writing an article for

Home Shop Machinist/Machinist's Workshop. Writing up this post has helped me organize my thoughts!