- Joined

- Dec 9, 2014

- Messages

- 59

Hello all,

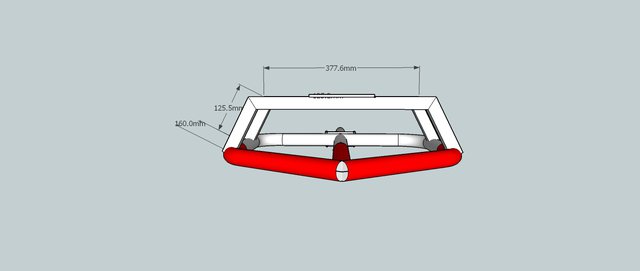

I am halfway through building a tricycle turned trike called a 'Gladiator Chopper Trike' and have come to a bit of an obstacle that wont effect the build immediately, but I'm a bit iffy about it for the future.

I have a split axle (after really researching I probably should have used a differential but I didn't know I was going to put a motor on it straight away), but the size of the axle is what im worried about, each axle has a 15" commodore car wheel on it with the centres cut out and spoked to the axle, so its not exactly easy to take the tire off to use a 1" or 1 1/4" axle instead.

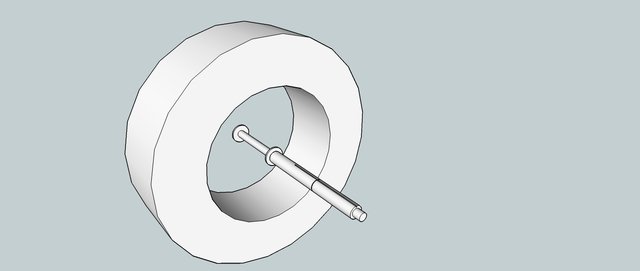

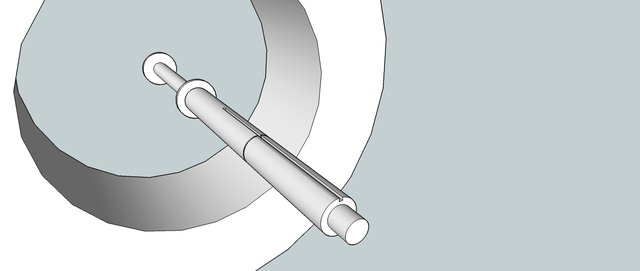

The two separate axles

The two rims and axles sanded and grinded down, with a bit of paint

The two wheels complete; spoked up with tires on

Axles are connected to the frame with pillow block bearings and two in the middle.

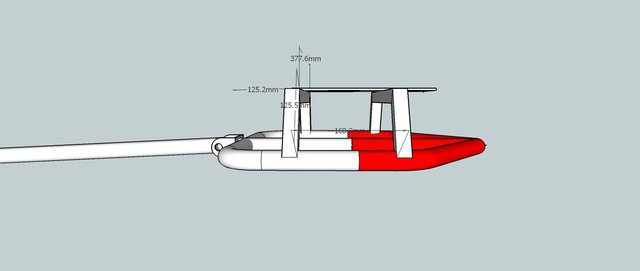

And finally the bike, near completion.

_________________________________________________________________________________________________

So now I ask the question, how can i beef up these axles? with a motor, a heavy rider and speeds around 30km an hour, the last thing you want is for your axle to give way and I'm not going to take the risk unless someone out there is 1000% positive and has proof that this wont break i just cant take the risk.

I will, of course, move the hubs/tires as close to the frame and bearings as I can to reduce that 'leaver' effect. I did think of drilling out a 1 1/4" piece of shaft, drilling from both ends to hollow out as long a piece as I can and then welding it as close to the hub as possible and changing the outside bearing to a 1 1/4" bearing, then drill out another one that would finish flush with the inner bearing and the first piece of drilled out shaft and that would mean that I could either cut a key way or grub screw my sprocket adapter into the 1 1/4" bar without any worries of it breaking on me.

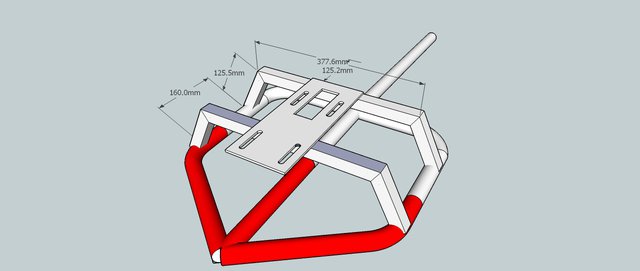

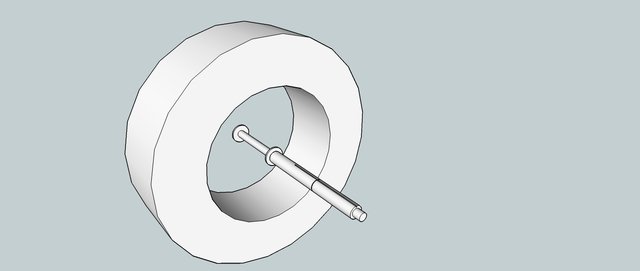

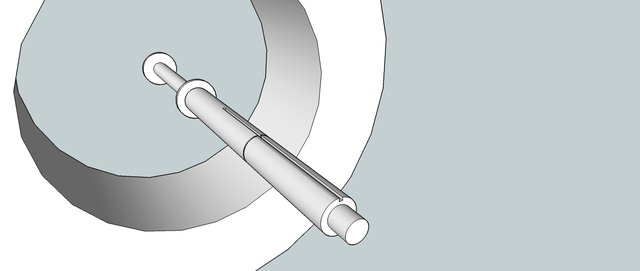

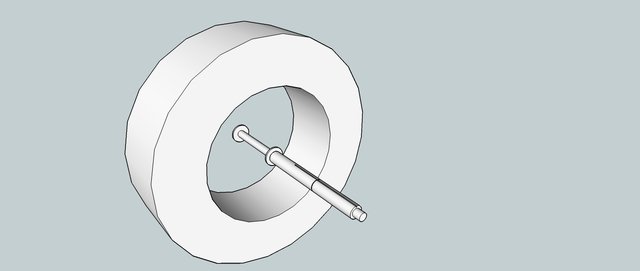

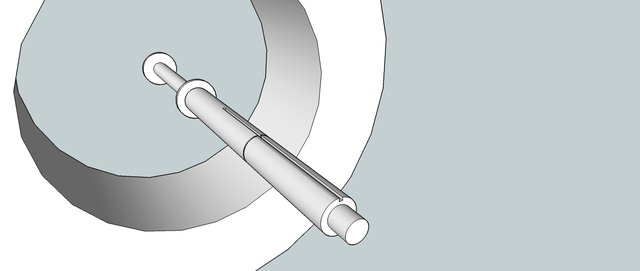

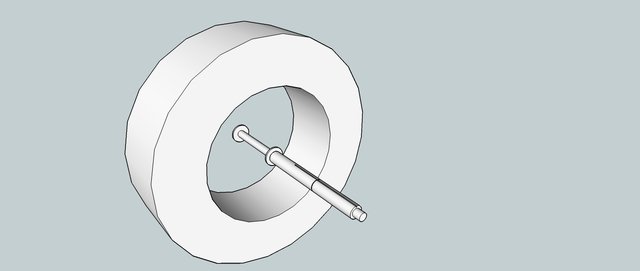

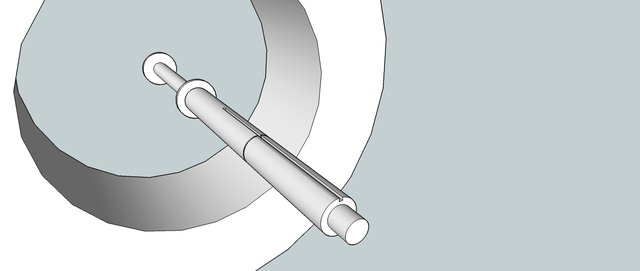

So it would look a little something like this

Thanks

little_sparky

I am halfway through building a tricycle turned trike called a 'Gladiator Chopper Trike' and have come to a bit of an obstacle that wont effect the build immediately, but I'm a bit iffy about it for the future.

I have a split axle (after really researching I probably should have used a differential but I didn't know I was going to put a motor on it straight away), but the size of the axle is what im worried about, each axle has a 15" commodore car wheel on it with the centres cut out and spoked to the axle, so its not exactly easy to take the tire off to use a 1" or 1 1/4" axle instead.

The two separate axles

The two rims and axles sanded and grinded down, with a bit of paint

The two wheels complete; spoked up with tires on

Axles are connected to the frame with pillow block bearings and two in the middle.

And finally the bike, near completion.

_________________________________________________________________________________________________

So now I ask the question, how can i beef up these axles? with a motor, a heavy rider and speeds around 30km an hour, the last thing you want is for your axle to give way and I'm not going to take the risk unless someone out there is 1000% positive and has proof that this wont break i just cant take the risk.

I will, of course, move the hubs/tires as close to the frame and bearings as I can to reduce that 'leaver' effect. I did think of drilling out a 1 1/4" piece of shaft, drilling from both ends to hollow out as long a piece as I can and then welding it as close to the hub as possible and changing the outside bearing to a 1 1/4" bearing, then drill out another one that would finish flush with the inner bearing and the first piece of drilled out shaft and that would mean that I could either cut a key way or grub screw my sprocket adapter into the 1 1/4" bar without any worries of it breaking on me.

So it would look a little something like this

Thanks

little_sparky