- Joined

- Dec 25, 2017

- Messages

- 141

Thank you all for the well-considered responses. Allow me to pull it together in summary and expand on the DC motor.

Again, please correct my mistakes and feel free to offer further advice.

1) Further mechanical drive ratio reduction.

@mksj has pointed out that a significant further gear reduction might be needed to drop the blade speed down to 300 SFM at max with electronic speed reduction from there. This would keep the motor up in higher torque values at speeds between 75-300 SFM. (Using a constant torque ratio of 4:1, common in many AC motors) He has further offered up a 10:1 Gear reduction box that could serve the purpose. This is the Tigear 17Q10R56. The cost is $200. See his post for details and a link.

This is most certainly the most simple and economic approach. Some machine work would be required to fabricate brackets to mount the motor and gearbox. The existing motor and VFD are retained. And, if the 10:1 reduction is used the SFM display on the VFD remains useful by dividing the display value by 10

2) Putting in a larger AC motor and VFD.

It looks like again we are limited by a constant torque speed ratio (CTSR) of around 10:1 for a good inverter motor. @mksj suggests a larger motor would still need a further gear reduction of maybe 4:1. This would bring down the max blade speed to around 750 SFM. Then 75 SFM is within reach with electronic speed reduction. A new motor and controller are required, along with some resizing of pulleys.

Here I have not picked out good example motors and controllers. The marketplace is vast and objective, quantitative, advice is hard to find. This is one reason for my generating this thread.

Here's a thought. Seems like 100:1 CTSR would do wonders for this saw. Is it possible to pick up low-speed torque by swapping the existing “unkown” motor with a better quality inverter-rated motor having 1000:1 CTSR and perhaps 1.5 HP? This is based on the idea that the root issue here is loss of torque at low speed. I don’t need more power, just need to retain torque at lower speed. Is it a given that doing this needs a new VFD?

Useful link I found:

https://www.woltersmotors.com/do-you-need-a-general-purpose-motor-or-an-inverter-duty-motor/

3) Going with variable speed DC

DC motors are famous for constant torque over a wide speed range.

http://www.drivesandautomation.co.uk/useful-information/dc-motor/#:~:text=DC motors can develop a,with a simple DC drive.

In fact, back in the early 70s my father put variable speed DC motors on his small Hardinge mill and Craftsman drill press. Oddly, his bandsaw got a complicated V-belt scheme.

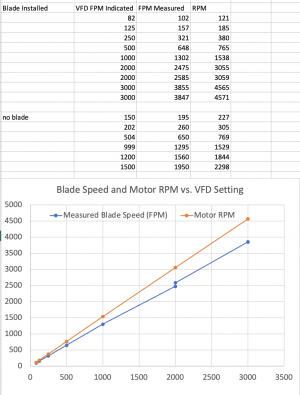

My own hunting has found a number of motors offering 20:1 “constant torque rating” and 1800 base RPM operation. Such a motor can be expected to run with near constant torque from 1800 RPM down to 90 RPM with steady torque by altering motor voltage while holding the armature current constant.

In my case this translates to blade speeds of 3000 SFM at 1800rpm down to 150 SFM at 90 RPM. A modest pulley change (smaller pulley on motor shaft) to drop the high-end speed down to 2000 SFM would shift the blade speed range to 2000 SFM on the high side and 100 SFM on the low side. If I can get away with a still-smaller pulley we can imagine 1000 SFM maximum and 50 SFM minimum.

While I am not sure how much DC HP is enough, I did some shopping at 1 and 1.5 HP.

1.5 HP

1.0 HP

Again, please correct my mistakes and feel free to offer further advice.

1) Further mechanical drive ratio reduction.

@mksj has pointed out that a significant further gear reduction might be needed to drop the blade speed down to 300 SFM at max with electronic speed reduction from there. This would keep the motor up in higher torque values at speeds between 75-300 SFM. (Using a constant torque ratio of 4:1, common in many AC motors) He has further offered up a 10:1 Gear reduction box that could serve the purpose. This is the Tigear 17Q10R56. The cost is $200. See his post for details and a link.

This is most certainly the most simple and economic approach. Some machine work would be required to fabricate brackets to mount the motor and gearbox. The existing motor and VFD are retained. And, if the 10:1 reduction is used the SFM display on the VFD remains useful by dividing the display value by 10

2) Putting in a larger AC motor and VFD.

It looks like again we are limited by a constant torque speed ratio (CTSR) of around 10:1 for a good inverter motor. @mksj suggests a larger motor would still need a further gear reduction of maybe 4:1. This would bring down the max blade speed to around 750 SFM. Then 75 SFM is within reach with electronic speed reduction. A new motor and controller are required, along with some resizing of pulleys.

Here I have not picked out good example motors and controllers. The marketplace is vast and objective, quantitative, advice is hard to find. This is one reason for my generating this thread.

Here's a thought. Seems like 100:1 CTSR would do wonders for this saw. Is it possible to pick up low-speed torque by swapping the existing “unkown” motor with a better quality inverter-rated motor having 1000:1 CTSR and perhaps 1.5 HP? This is based on the idea that the root issue here is loss of torque at low speed. I don’t need more power, just need to retain torque at lower speed. Is it a given that doing this needs a new VFD?

Useful link I found:

https://www.woltersmotors.com/do-you-need-a-general-purpose-motor-or-an-inverter-duty-motor/

3) Going with variable speed DC

DC motors are famous for constant torque over a wide speed range.

http://www.drivesandautomation.co.uk/useful-information/dc-motor/#:~:text=DC motors can develop a,with a simple DC drive.

In fact, back in the early 70s my father put variable speed DC motors on his small Hardinge mill and Craftsman drill press. Oddly, his bandsaw got a complicated V-belt scheme.

My own hunting has found a number of motors offering 20:1 “constant torque rating” and 1800 base RPM operation. Such a motor can be expected to run with near constant torque from 1800 RPM down to 90 RPM with steady torque by altering motor voltage while holding the armature current constant.

In my case this translates to blade speeds of 3000 SFM at 1800rpm down to 150 SFM at 90 RPM. A modest pulley change (smaller pulley on motor shaft) to drop the high-end speed down to 2000 SFM would shift the blade speed range to 2000 SFM on the high side and 100 SFM on the low side. If I can get away with a still-smaller pulley we can imagine 1000 SFM maximum and 50 SFM minimum.

While I am not sure how much DC HP is enough, I did some shopping at 1 and 1.5 HP.

1.5 HP

- DC motor from Automation Direct, 180 VDC, 1800 RPM $410

- 20:1 constant torque rating

- MTPM-1P5-1L18

- https://www.automationdirect.com/adc/shopping/catalog/motors/dc_motors/general_purpose/mtpm-1p5-1m18

- DC Motor Drive, analog, from Automation Direct $329

- Rated 0.25 – 2 HP @ 180V

- GSD5-240-10N4

- https://www.driveswarehouse.com/s-150a

1.0 HP

- A combo package from Drives Warehouse

- SP-101 analog controller & E101AM-P motor $615

- Motor is 1 HP, 180 VDC, 1750 RPM

- https://www.driveswarehouse.com/sp-101-e101am-p