-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

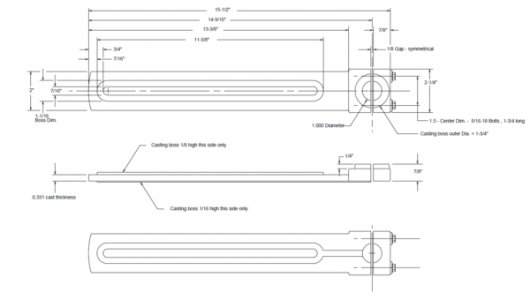

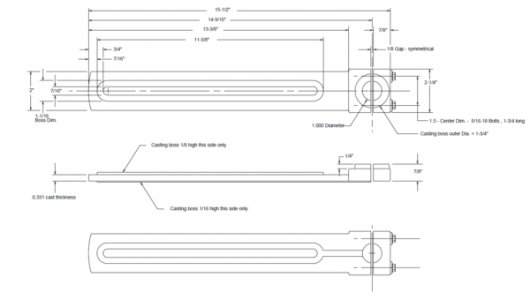

Atlas Mill M1-61 drawings

- Thread starter Airpirate

- Start date

- Joined

- Mar 3, 2013

- Messages

- 1,448

Found it right here on this site!

http://www.hobby-machinist.com/resources/atlas-m1-61-arbor-support-bar-pdf.1486/

Edited 6/20/2017 Updated link to point to new location

http://www.hobby-machinist.com/resources/atlas-m1-61-arbor-support-bar-pdf.1486/

Edited 6/20/2017 Updated link to point to new location

Last edited:

- Joined

- Mar 3, 2013

- Messages

- 1,448

Rudy Kouhoupt also wrote a few articles in "The Home Shop Machinist" called "An Atlas Mill Update". Part 1 was published in the July/August 2001 issue. It has diagrams and instructions for making one. It doesn't appear that back issues that old are still available. It may be contained in one of the collections but I'm not sure. You may want to try your local library.

- Joined

- Mar 3, 2013

- Messages

- 1,448

Thank you very much. I searched this site quite a while with no luck. How did you find it?

Never give up

I believe it was on the last page of Atlas documents.

- Joined

- Dec 25, 2011

- Messages

- 10,510

The original M1-61 Support Bar was made in one piece of cast iron. After the two clamping screw holes were drilled, reamed and tapped, the saddle bar was sawed off with a 1/8" thick slitting saw.

Comments on using or looking for anything in Downloads -

First, read the instructions in the Sticky Area at the top of this forum.

Because the Xenforo RESOURCES module, which was modified by the List Owner for use as a file DOWNLOADS module, has absolutely no sort capability, and the fact that there are nearly 2000 files currently in the system, and about 10% are Atlas, I created a lot of Categories (Folders or Directories and Sub-Directories) and in most cases was able in the lowest sub-directories to limit the page counts to 1. So you should never have to search more than one page of files. But before you start looking at file names in the right pane, first drill down to the lowest sub-directory or folder or category. Which in the current case is Atlas Mill Drawings.

I apologize for forgetting to put the Atlas part number (M1-61) into the Title. I just fixed that. And I also somehow on the same day uploaded two copies of the same drawing. I just fixed that, too.

Finally, if your mill wasn't originally a "C" model (MFC, etc.), there are three other parts (M1-60. M1-66 and M1-67) that you will have to make before you can use the support bar. I have the factory drawings for those and will upload them in a day or two. The reason that I haven't already is probably because when I got the drawings from Clausing, the M1-61 drawing was absolutely terrible. And I got bogged down in trying to clean it up, got tired of working on it for a while, and forgot to upload the other drawings.

I don't know who drew the drawing that is in Downloads. I have not checked his dimensions against the factory drawing because at the moment, they are illegible.

Comments on using or looking for anything in Downloads -

First, read the instructions in the Sticky Area at the top of this forum.

Because the Xenforo RESOURCES module, which was modified by the List Owner for use as a file DOWNLOADS module, has absolutely no sort capability, and the fact that there are nearly 2000 files currently in the system, and about 10% are Atlas, I created a lot of Categories (Folders or Directories and Sub-Directories) and in most cases was able in the lowest sub-directories to limit the page counts to 1. So you should never have to search more than one page of files. But before you start looking at file names in the right pane, first drill down to the lowest sub-directory or folder or category. Which in the current case is Atlas Mill Drawings.

I apologize for forgetting to put the Atlas part number (M1-61) into the Title. I just fixed that. And I also somehow on the same day uploaded two copies of the same drawing. I just fixed that, too.

Finally, if your mill wasn't originally a "C" model (MFC, etc.), there are three other parts (M1-60. M1-66 and M1-67) that you will have to make before you can use the support bar. I have the factory drawings for those and will upload them in a day or two. The reason that I haven't already is probably because when I got the drawings from Clausing, the M1-61 drawing was absolutely terrible. And I got bogged down in trying to clean it up, got tired of working on it for a while, and forgot to upload the other drawings.

I don't know who drew the drawing that is in Downloads. I have not checked his dimensions against the factory drawing because at the moment, they are illegible.

- Joined

- Mar 3, 2013

- Messages

- 1,448

What type steel would be best to make this from?

Rudy Kouhoupt doesn't specify the type of steel used he just says "steel". He used a 0.25" thick x 1.5" wide bar for the slotted section and a 0.75" x 2.5" for the clamping part.

- Joined

- May 4, 2015

- Messages

- 3,583

I have a question , would 1" x 3" x 16" aluminum bar work . If left a bit thicker say 3/4" on the top slotted part be strong enough? Just asking I need to or want to build one for mine . If I ever get fixed up by drs. 1" x 3" cast iron my be hard to come by.

One on eBay selling price $335.00 just for that support bar . But there hard to find I guess .

One on eBay selling price $335.00 just for that support bar . But there hard to find I guess .

- Joined

- Feb 24, 2017

- Messages

- 56

There is a guy who makes accessories for the atlas at mymachineshop.net who sells one for 199.00 but since you have a machine and a couple threads up there is a drawing whay not make one from medium or low carbons steel stock. I also bought a arbor and draw in bar from mymachineshop.net fair prices.

Aluminum might work but the attachment points might tend to wear in. Maybe T3 or T4 might work.

Aluminum might work but the attachment points might tend to wear in. Maybe T3 or T4 might work.

Last edited: