Hi, i'm very new to the lathe so i dont know very many term's or what parts are called

i've done a fair amount of research and printed off a manual ect which altho nice to have dont really help, i'm in need of experience/advice

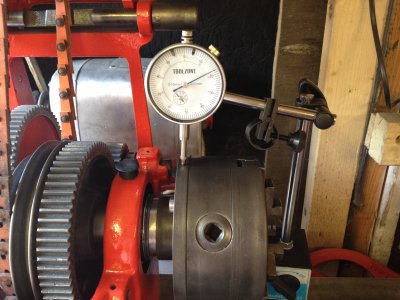

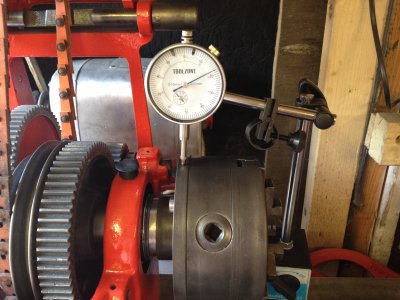

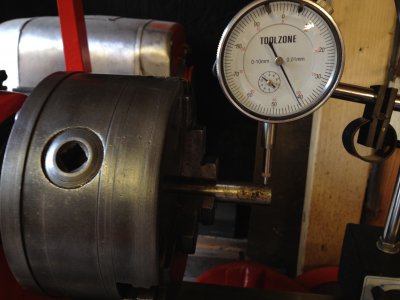

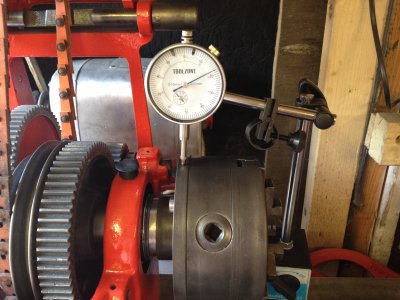

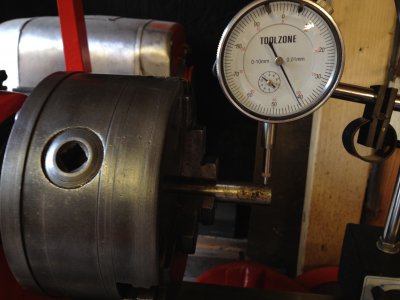

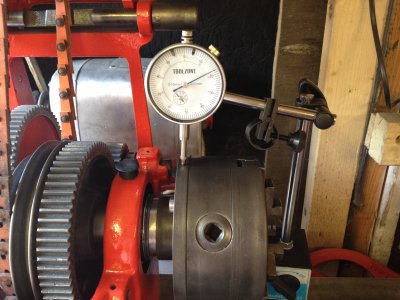

So it a Atlas 10D made approx 1936-37 with timken bearings and i have alot of wobble/runout?

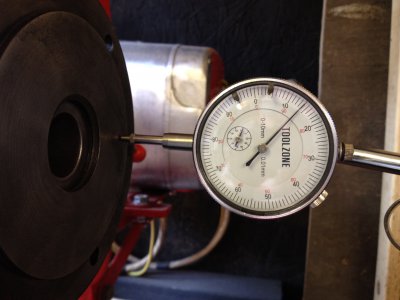

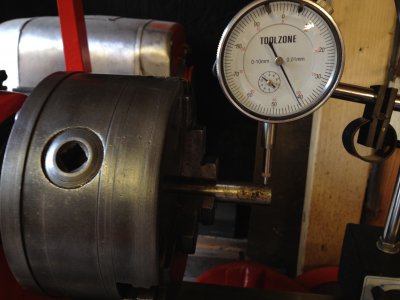

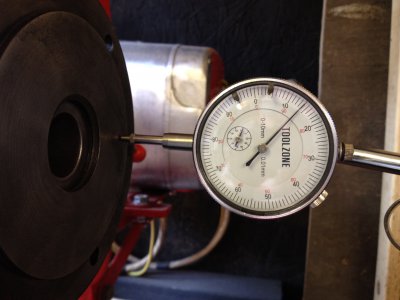

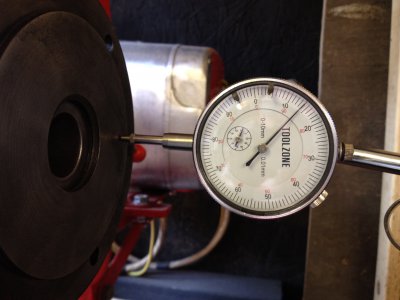

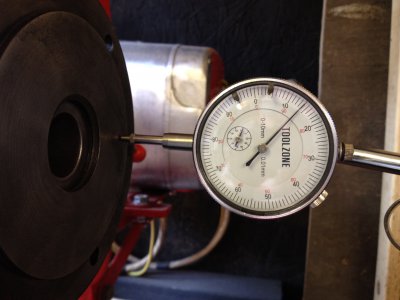

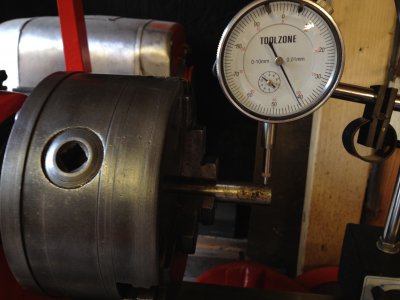

the part that the chuck screws onto seems ok with a readout of 1 in error but upto 41 out of the chuck

i have a 3 jaw and i think original Atlas 4 jaw both have pretty much the same error

Anybody know what the hell i'm talking about?

i've done a fair amount of research and printed off a manual ect which altho nice to have dont really help, i'm in need of experience/advice

So it a Atlas 10D made approx 1936-37 with timken bearings and i have alot of wobble/runout?

the part that the chuck screws onto seems ok with a readout of 1 in error but upto 41 out of the chuck

i have a 3 jaw and i think original Atlas 4 jaw both have pretty much the same error

Anybody know what the hell i'm talking about?