What do you guys think of this?

An update:

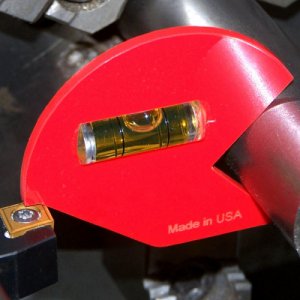

I purchased one for myself and it arrived yesterday so I though I would give an evaluation. I got mine through eBay for $10.95, shipping included.

The level vial is sensitive enough to detect a 1.5 mil feeler gauge inserted between the tool bit and the gage. The sensitivity is determined by the distance between the contact point on the upper surface of the tool and the center of the round so it will be less sensitive with a larger diameter cylinder. I used a 3/4" pin for the evaluation but also checked performance with .170" and 2.000" rounds.

Although the gage's function is to set tool height to be on line with the spindle axis, it is also possible to accurately set the tool height above or below the axis. To set below the axis, a feeler gauge or pin gage equal to the amount of drop is placed between the tool and the gage's measuring surface. To set above, if some some reason, you wish to do so, place a feeler gage equal to 1.414 times the amount of rise desired between bottom edge of the 90 deg. vee, thereby lifting the center line of the gage by the amount of rise.

The lower flat surface is parallel to the level vial, making it a convenient way to check the level of your cross slide ways. If the cross slide ways reads off level, you can still use the gage by adjusting your tool height to read the same as it does on the ways.

In conclusion, this tool is the most accurate means of measuring lathe tool height that I have used. Additionally, for on center alignment, it is on a par with the vertical rule method for ease of use. Its use requires a cylindrical surface between .2 and 2" in diameter concentric with the spindle axis but this is not a particular handicap with lathe work. Should one be running a facing operation and not have a cylindrical surface, a pin can be inserted in the tailstock chuck and the measurement made there.

Bob