-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

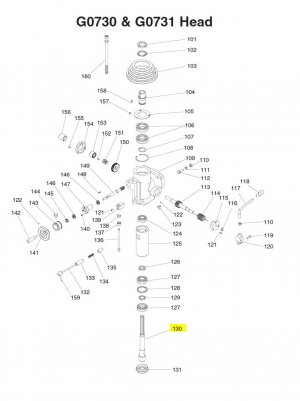

Anyone removed spindle/quill on G0730 style knee mill?

- Thread starter r-mm

- Start date

- Joined

- Dec 12, 2016

- Messages

- 496

I have rebuild the spindle on my Rockwell, it is similar but may not be the same.

You will want to at least loosen and remove the retaining nut (131) while still on the mill with the quill locked. It probably takes a spanner, and could be very tight. I ended up making a custom spanner for mine.

After that you drop the quill, which can be done after the feed shaft (113) and related parts are removed. It will simply drop out. It has some weight so be careful.

There is likely a circlip near the top of the spindle that has to be removed, above the upper bearing, then it should drop out (or can be pressed out) of the quill.

There is generally a nut securing the bottom bearings on the quill. Once removed you should be able to pull the bearings.

You will want to at least loosen and remove the retaining nut (131) while still on the mill with the quill locked. It probably takes a spanner, and could be very tight. I ended up making a custom spanner for mine.

After that you drop the quill, which can be done after the feed shaft (113) and related parts are removed. It will simply drop out. It has some weight so be careful.

There is likely a circlip near the top of the spindle that has to be removed, above the upper bearing, then it should drop out (or can be pressed out) of the quill.

There is generally a nut securing the bottom bearings on the quill. Once removed you should be able to pull the bearings.

- Joined

- Feb 17, 2013

- Messages

- 4,406

Just a quick word ... don't do what I did! I'd failed to notice that the retaining nut on my PM knee mill was locked in place by a setscrew on the back side of the spindle. Kinda boogered the threads getting it off. Also note that (at least on mine) the threads are left-hand.

Thanks guys I think I understand how to remove the quill Drive gear but not certain I understand whether or not it’s possible to remove the spindle with the Quill in place. Is it a mild or full press fit making this impossible? Or does number 104 or other retain the spindle in someway?

- Joined

- Nov 17, 2017

- Messages

- 1,525

Doubleboost disassembled his smaller cousin to that knee mill in a video about 6-8 months ago to find a dead bearing.

It seems to come out rather easily once the rack is removed, and the drawbar removed.

It seems to come out rather easily once the rack is removed, and the drawbar removed.

- Joined

- Dec 12, 2016

- Messages

- 496

I think that most of these types of mills will not have an oil seal. I added one to my Rockwell myself, using a crankshaft front housing seal.