- Joined

- Aug 31, 2014

- Messages

- 50

Hi, I am still busy with my wheel spacers. The progress a a bit slow. I have a couple of questions.

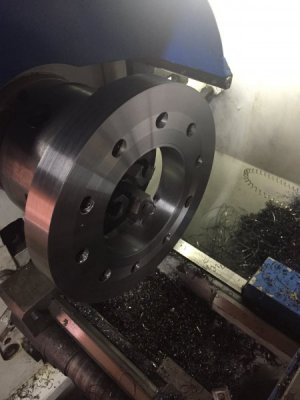

After I drilled the holes. I fitted the spacer on the wheel hub. It fits nicely over the hub and wheel nuts, but it is too thick. The wheel hub don't protrude. The thickness of the spacer is 38mm, so I am machining it down to 30mm to give the wheel a 8mm shoulder to rest on. My problem is that the holes are all drilled and I am taking interrupted cuts now. I dialed in the spacer on the chuck, but when I take facing cuts over the holes it vibrates. I tried HSS tool bits , but the holes eats it up. I had the best luck with Carbide inserts but at 380rpm it makes sparks, and if I feed it from the outside in it begins to cut taper after the holes.

How do I prevent the sparks? Lower RPM?

How do I prevent the Vibration? Lower RPM? Smaller cuts?

How do I prevent the tool from cutting taper? Tool blunt?

After I drilled the holes. I fitted the spacer on the wheel hub. It fits nicely over the hub and wheel nuts, but it is too thick. The wheel hub don't protrude. The thickness of the spacer is 38mm, so I am machining it down to 30mm to give the wheel a 8mm shoulder to rest on. My problem is that the holes are all drilled and I am taking interrupted cuts now. I dialed in the spacer on the chuck, but when I take facing cuts over the holes it vibrates. I tried HSS tool bits , but the holes eats it up. I had the best luck with Carbide inserts but at 380rpm it makes sparks, and if I feed it from the outside in it begins to cut taper after the holes.

How do I prevent the sparks? Lower RPM?

How do I prevent the Vibration? Lower RPM? Smaller cuts?

How do I prevent the tool from cutting taper? Tool blunt?