- Joined

- Jun 12, 2014

- Messages

- 5,055

As a hobbyist and "amateur" machinist, I am always learning and trying new designs for the things I build an my VFD control systems, which I occasionally make for others. I am always trying to optimize the builds through better deigns, safety features, use of good quality components and trying to make the installs easier. I have posted a number of VFD control systems designs and programming recommendations. Some I have built, other I have not, so their use is at your own risk/responsibility but are good starting points/information. At this time if someone is building their own lathe VFD system, I usually recommend they go with a single relay design. It works well and most people feel comfortable with that level of build/installation. Programming the VFD is a challenge, but suggestions for the parameters files on the WJ200 have been previously posted which should help with the intimidation factor of the manuals.The single relay design is specific for use with the Hitachi WJ200 VFD and should not be used (nor will work) with other VFDs.

When I do a build for other hobbyists, I use a more complex VFD control design system that I have evolved through the years, which uses a 4 relay design: a control system power relay, Forward/Reverse relays and a coolant relay/contactor. I use the 4 relay system with an external power supply, so the majority of the VFD input switching is done in the control box, and there are 2 to 3 redundant safety logic events for any control to operate. The E-Stop kills the power relay, which shuts down both the VFD inputs, and the other control relays. It also issues a fast stop command to the VFD and prevents restart if power is lost. I feel this is better than disconnecting the VFD input power. It is also possible to program the VFD output section to shut down, but you would lose the benefits of the quick braking. The coolant circuit can be 24VDV, 120VAC or 240VAC with fusing or a thermal overload. I always fuse or use a thermal motor relay for a 120/240VAC coolant pump, something that is not done on the stock 1340GT machine with this option. The other main limitation with the PM1340GT lathe is a tinny control box on the machine, which is very limiting space wise. I have found only one 24VDC 100W power supply that will fit in the control box. I also use a step down converter to provide 12VDC for some of the sub systems. On some VFD builds I put the power supply in the VFD cabinet. I have been wiring 4 wire power to most of my machines, I pull off a neutral and 120VAC which goes to a separate breaker in the VFD box and then can power 120VAC sockets. On the mill this is very handy for the DRO, drives and lights if they use 120VAC.

I have wanted to make installation of the VFD systems easier, and have long toyed with the idea of using cable sockets as opposed to a terminal block to make the many connections when installing these systems. The main limitations has been cost, finding a 12 pin bulkhead socket that mounts from the back of the cabinet and a cable that has the appropriate gauge wire but is not too big. Most socket/cables of this variety can be around $100, so on my most recent build I decided to do all the cable connectors/fabrication from parts. The positive side is it worked very nicely, the down side is it took hours to assemble and connecting twelve 22g wires/insulating on both sides was a chore. My eyes were not happy either. I did use a premade bulkhead socket for the proximity sensor cable, I will keep this for future builds. When I benched tested the system, it went together very quickly and worked as expected, but I do not plan on doing anymore this way unless I can find a premade assembly that is inexpensive.

I have attached two schematics for the 4 relay system, one is setup for a 24VDC coolant circuit with a OFF-ON twist switch designed to be used with a 24VDC air solenoid coolant system. The coolant only runs when the spindle is turning. The other design is similar but uses the factory 240VAC single phase coolant pump, the ON-OFF-ON maintained switch either will run the coolant continuously or only when the spindle is turning.

I have included some pictures to show the basic layouts schematics and basic programming parameters for the WJ200 using these system designs. The wiring, cabling is fairly detailed, and I primarily use shielded cable with a star ground system at the VFD. Sourcing parts can be a problem, but a lot of this is planning and getting everything you think you need. I use Automation Direct for a number of parts, good quality at reasonable prices. Hope this information is useful to others.

Mark

240VAC Coolant system with fusing.

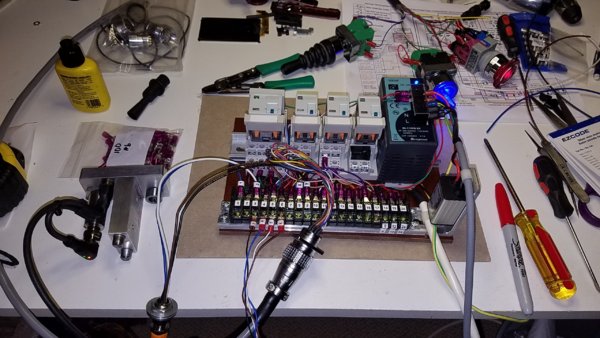

24VDC Coolant system with control system disconnects being tested on the bench.

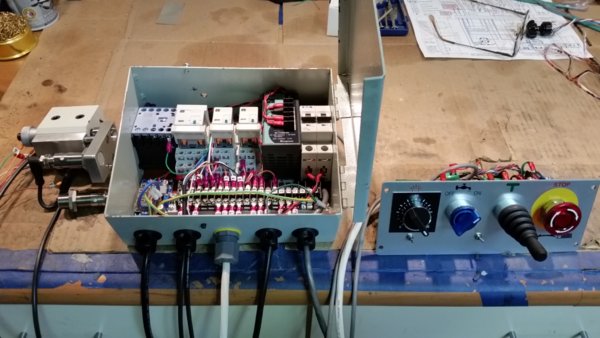

Installed system with 240VAC coolant contactor and Breaker. Not much space leftover.

When I do a build for other hobbyists, I use a more complex VFD control design system that I have evolved through the years, which uses a 4 relay design: a control system power relay, Forward/Reverse relays and a coolant relay/contactor. I use the 4 relay system with an external power supply, so the majority of the VFD input switching is done in the control box, and there are 2 to 3 redundant safety logic events for any control to operate. The E-Stop kills the power relay, which shuts down both the VFD inputs, and the other control relays. It also issues a fast stop command to the VFD and prevents restart if power is lost. I feel this is better than disconnecting the VFD input power. It is also possible to program the VFD output section to shut down, but you would lose the benefits of the quick braking. The coolant circuit can be 24VDV, 120VAC or 240VAC with fusing or a thermal overload. I always fuse or use a thermal motor relay for a 120/240VAC coolant pump, something that is not done on the stock 1340GT machine with this option. The other main limitation with the PM1340GT lathe is a tinny control box on the machine, which is very limiting space wise. I have found only one 24VDC 100W power supply that will fit in the control box. I also use a step down converter to provide 12VDC for some of the sub systems. On some VFD builds I put the power supply in the VFD cabinet. I have been wiring 4 wire power to most of my machines, I pull off a neutral and 120VAC which goes to a separate breaker in the VFD box and then can power 120VAC sockets. On the mill this is very handy for the DRO, drives and lights if they use 120VAC.

I have wanted to make installation of the VFD systems easier, and have long toyed with the idea of using cable sockets as opposed to a terminal block to make the many connections when installing these systems. The main limitations has been cost, finding a 12 pin bulkhead socket that mounts from the back of the cabinet and a cable that has the appropriate gauge wire but is not too big. Most socket/cables of this variety can be around $100, so on my most recent build I decided to do all the cable connectors/fabrication from parts. The positive side is it worked very nicely, the down side is it took hours to assemble and connecting twelve 22g wires/insulating on both sides was a chore. My eyes were not happy either. I did use a premade bulkhead socket for the proximity sensor cable, I will keep this for future builds. When I benched tested the system, it went together very quickly and worked as expected, but I do not plan on doing anymore this way unless I can find a premade assembly that is inexpensive.

I have attached two schematics for the 4 relay system, one is setup for a 24VDC coolant circuit with a OFF-ON twist switch designed to be used with a 24VDC air solenoid coolant system. The coolant only runs when the spindle is turning. The other design is similar but uses the factory 240VAC single phase coolant pump, the ON-OFF-ON maintained switch either will run the coolant continuously or only when the spindle is turning.

I have included some pictures to show the basic layouts schematics and basic programming parameters for the WJ200 using these system designs. The wiring, cabling is fairly detailed, and I primarily use shielded cable with a star ground system at the VFD. Sourcing parts can be a problem, but a lot of this is planning and getting everything you think you need. I use Automation Direct for a number of parts, good quality at reasonable prices. Hope this information is useful to others.

Mark

240VAC Coolant system with fusing.

24VDC Coolant system with control system disconnects being tested on the bench.

Installed system with 240VAC coolant contactor and Breaker. Not much space leftover.

Attachments

-

PM1340GT WJ200 SUGGESTED VFD CONTROL SYSTEM PROGRAMMING PARAMETERS FOR 4 RELAY CONTROL SYSTEM.pdf2.6 MB · Views: 691

-

PM1340GT WJ200 schematic, Proximity SW, E-Stop, 2-stage Braking, Joystick JOG, Coolant SW.pdf727.9 KB · Views: 589

-

PM1340GT WJ200 schematic, Proximity SW, E-Stop, 2-stage Braking, Joystick JOG, Coolant 2 way.pdf727.4 KB · Views: 551