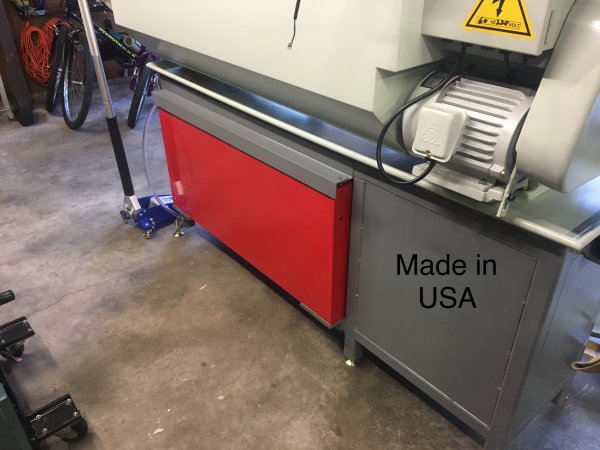

Great job, I love the added drawers.

Here are the drawings (such as they are) for the stand as I built mine. I modified the HF tool box on mine by removing the lid and trimming the top flange. Only done to minimize the gap around the box when it's installed in the stand frame. Adjust the dimensions for the box you use.

Order on assembly:

1. Assemble the 2 end sections.

2. Using the 4 long tubes connect the 2 end sections. Keep every thing tacked at this point.

3. Fill in the rest of the tubes and install the feet.

4. Install the shelf pieces.

5. Weld the frame assembly. Move around when welding to minimize distortion.

6. Install the sheet metal filler pieces.

7. Once the frame is fully welded time to setup the mount plates. The goal is to get the 2 plates aligned in the horizontal plane. I used 2 heavy wall square tubes with the 2 plates clamped to them. I then tacked the plates to the frame. I did a test fit by mounting the lathe on the stand before final welding of the mounts. I then did a few 1" stitch welds.

7.1 Instead of 2 mount plates you can use a one piece plate. It's important to get the flattest plate you can.

I used .120" wall tubing, a good improvement would be .250".

I wanted the "one piece cast look" so all welds were ground smooth and filler was used before paint. The sheet metal filler plates were designed with this in mind. Less work would be to stitch weld them on the inside and leave the outside as is. Laser cut parts have a finished looking edge so I think this would be a good look.

The drawers are another great addition.