Long time lurker but first time actually joining and posting on a forum such as this...and I am glad I joined!

Little back story first, I have lurked on various machinist sites looking for answers and simply looking at what others are doing with their various machines. I hold a full-time job, like most I imagine, and tinker on the weekends. I got into building trucks, specifically older Toyota's. I cringed every time I had to take something I was working on to a 'specialist' because I lacked the skills to do it myself. The day came when I paid that final invoice and told myself that something has got to give,so I decided to finally educate myself on the art of metalcraft. I started with over a year long welding course at the local community college, I had welded for years but not to my satisfaction. I finished up, obtaining several certifications in 3 processes. I now had the confidence, a big step for me, to do it myself.

Fast forward a year and I see the local college is offering a CNC machinist course...seeming that I has earlier acquired an Atlas TH 54 lathe, I best learn how to properly utilize it and recognize it's limits. Then I was struck with the sickness for all things made of old iron, made in the USA, and had everything to do with metal working.

To make a long, boring story...short, I happened upon a Clausing 8520 on CL...just a couple hours away...i pondered and figured out a plan to run it by the Chief Financial Officer....the wife! Once convinced, I had the ok to add to the collection of old iron. By then, the ad was 3 days old! Reading on some of the sites, it seemed that this particular mill comes up every so often and sold even faster! I knew I was too late but attempted to contact the seller. After a short time I got a response.."Still available but lots of interest". I asked when it was convenient to call and he responded he was boarding a plane and would call me in 2 hours! I didn't hold my breathe...But he stayed true and called me once he landed. We spoke briefly and he explicitly explained that he was not a machinist and didn't know much, so please use plain language! I chuckled and assured him that we were in the same boat.

I asked the typical questions....condition, damage, did it function properly. All seemed to check out, at least without seeing it. I told him I would call him later with an answer as I pondered the potential success or utter failure of purchasing something site unseen. We settled on a price, lower than his asking, due to the fact that during our conversation, he mentioned that 'sometimes the spindle gives him problems'. Hmmm....bearings....bent quill....or was it just another clapped out machine.

Fast forward and we arranged to meet to look at the mill. I loaded the trailer and headed out...wondering if this would it be a wasted trip. We finally met and turned out the mill was better than expected. He had to relocate due to employment and didn't want to move the mill again.

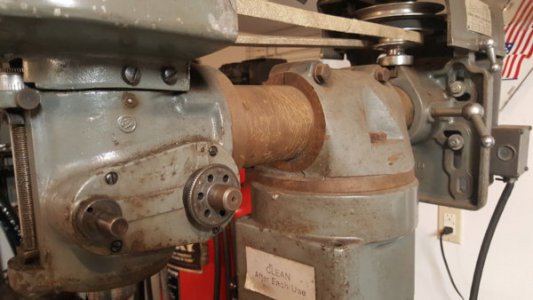

I know....without pics, it didn't happen so here are a few. I will let the fellow members of the forum judge....I will only say that it runs smooth, the X and Y axis runs smooth and still feels tight with very little play on the X axis. I noticed no problems with the spindle...however the fine feed will not engage sometimes....figured it was the gears I had read about. I did disassemble but find no broken teeth but I will clean and see how it goes. I do have a smidgen of bearing noise from the motor and it is unknown to me if I can oil the bearing in the motor...I'll have to wait and see what you all say. The on

ly damage I did notice was on the Y axis handle, bent, but does not effect anything that I can tell...as of yet. So here you go....what do you guys think?

ly damage I did notice was on the Y axis handle, bent, but does not effect anything that I can tell...as of yet. So here you go....what do you guys think?

Thanks for enduring through my first post...long boring, yada, yada, yada... View attachment 143594

Little back story first, I have lurked on various machinist sites looking for answers and simply looking at what others are doing with their various machines. I hold a full-time job, like most I imagine, and tinker on the weekends. I got into building trucks, specifically older Toyota's. I cringed every time I had to take something I was working on to a 'specialist' because I lacked the skills to do it myself. The day came when I paid that final invoice and told myself that something has got to give,so I decided to finally educate myself on the art of metalcraft. I started with over a year long welding course at the local community college, I had welded for years but not to my satisfaction. I finished up, obtaining several certifications in 3 processes. I now had the confidence, a big step for me, to do it myself.

Fast forward a year and I see the local college is offering a CNC machinist course...seeming that I has earlier acquired an Atlas TH 54 lathe, I best learn how to properly utilize it and recognize it's limits. Then I was struck with the sickness for all things made of old iron, made in the USA, and had everything to do with metal working.

To make a long, boring story...short, I happened upon a Clausing 8520 on CL...just a couple hours away...i pondered and figured out a plan to run it by the Chief Financial Officer....the wife! Once convinced, I had the ok to add to the collection of old iron. By then, the ad was 3 days old! Reading on some of the sites, it seemed that this particular mill comes up every so often and sold even faster! I knew I was too late but attempted to contact the seller. After a short time I got a response.."Still available but lots of interest". I asked when it was convenient to call and he responded he was boarding a plane and would call me in 2 hours! I didn't hold my breathe...But he stayed true and called me once he landed. We spoke briefly and he explicitly explained that he was not a machinist and didn't know much, so please use plain language! I chuckled and assured him that we were in the same boat.

I asked the typical questions....condition, damage, did it function properly. All seemed to check out, at least without seeing it. I told him I would call him later with an answer as I pondered the potential success or utter failure of purchasing something site unseen. We settled on a price, lower than his asking, due to the fact that during our conversation, he mentioned that 'sometimes the spindle gives him problems'. Hmmm....bearings....bent quill....or was it just another clapped out machine.

Fast forward and we arranged to meet to look at the mill. I loaded the trailer and headed out...wondering if this would it be a wasted trip. We finally met and turned out the mill was better than expected. He had to relocate due to employment and didn't want to move the mill again.

I know....without pics, it didn't happen so here are a few. I will let the fellow members of the forum judge....I will only say that it runs smooth, the X and Y axis runs smooth and still feels tight with very little play on the X axis. I noticed no problems with the spindle...however the fine feed will not engage sometimes....figured it was the gears I had read about. I did disassemble but find no broken teeth but I will clean and see how it goes. I do have a smidgen of bearing noise from the motor and it is unknown to me if I can oil the bearing in the motor...I'll have to wait and see what you all say. The on

ly damage I did notice was on the Y axis handle, bent, but does not effect anything that I can tell...as of yet. So here you go....what do you guys think?

ly damage I did notice was on the Y axis handle, bent, but does not effect anything that I can tell...as of yet. So here you go....what do you guys think?Thanks for enduring through my first post...long boring, yada, yada, yada... View attachment 143594

Last edited: