- Joined

- Jun 26, 2014

- Messages

- 619

I'm on a mission to try and finish off an embarrassingly long list of started, or equipment purchased for, but unfinished projects before I started/spend more money on anything new (I know there will be relapses along the way but at least it is a goal to aim for).

One such project that I had purchased all the equipment for but never go around to actually doing was to add a TouchDRO to my mill and lathe. (http://www.yuriystoys.com/p/android-dro.html)

I had purchased the basic iGaging remote display scales with the intension of getting them set up and working individually before interfacing them to a TouchDRO controller and tablet, so today I started with:

Mill X-Axis Scale Install

Like most people I think , I had originally hoped to install the X-Axis scale at the back of the table so it would be out of the way but eventually came to the conclusion that it would impact the Y-Axis travel too much. My mill only has about 5" of Y travel and at the extreme the table is hard up against the column so any installation at the back of the table would effectively lose about an inch of the available travel which was undesirable.

I also looked at the possibility of installing the scale under the table next to the lead screw but there just wasn't enough space. So in the end an installation at the front of the table was decided on.

My mill table has a T-Slot along the front which I had used for movable stops that I found very useful so this was a reluctant decision, but the only alternative I could find would of reduced by Y travel to 4" which would of been a bigger loss.

I decided to use the T-Slot for mounting and make it removable so I could avoid any drilling or permanent modification to the mill. By making new custom mounting brackets for the scale I also hope to crimp a little extra range from the standard 12"/300mm iGaging scale. My mill's X-Axis travel is 315mm and I was too cheap to buy a 24"/600mm scale and cut it in half. A 12" scale is actually 305mm of travel and has about 10mm of the scale clamped in the supplied brackets at each end. By reducing the amount of the scale in the mounting to 3 or 4 mm at each end I figures I could gain an extra 10 to 15mm and cover the entire possible physical travel of my table with a "12 inch" scale.

So after machining up two new end bracket that attach to the T-Slot and had a shallow milled pocket for the scale ends to fit into, and a bracket for the reader that fixed to two unused tapped holes that were added by the previous owner I had an installation that required no additional modification to the mill and can be easily removed is necessary.

The components:

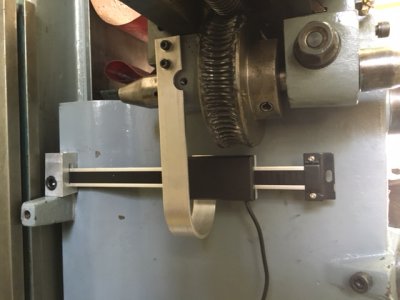

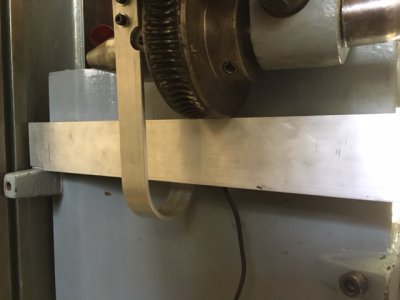

Installed:

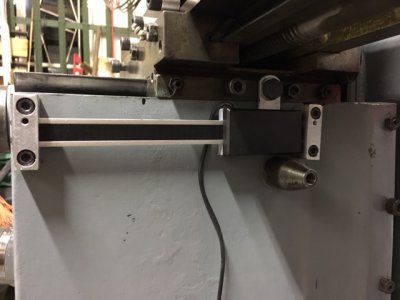

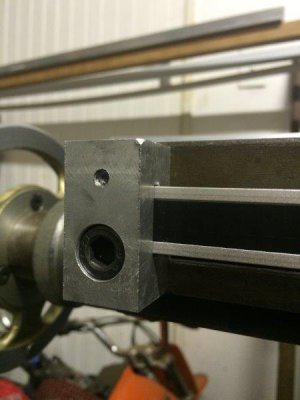

Scale Bar Bracket:

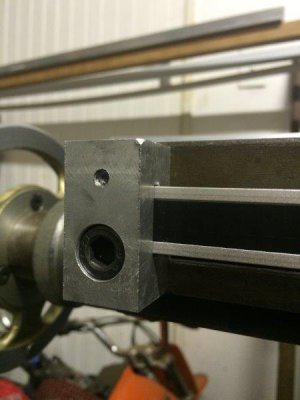

Reader Bracket:

And with cover installed:

One down, two to go.

One such project that I had purchased all the equipment for but never go around to actually doing was to add a TouchDRO to my mill and lathe. (http://www.yuriystoys.com/p/android-dro.html)

I had purchased the basic iGaging remote display scales with the intension of getting them set up and working individually before interfacing them to a TouchDRO controller and tablet, so today I started with:

Mill X-Axis Scale Install

Like most people I think , I had originally hoped to install the X-Axis scale at the back of the table so it would be out of the way but eventually came to the conclusion that it would impact the Y-Axis travel too much. My mill only has about 5" of Y travel and at the extreme the table is hard up against the column so any installation at the back of the table would effectively lose about an inch of the available travel which was undesirable.

I also looked at the possibility of installing the scale under the table next to the lead screw but there just wasn't enough space. So in the end an installation at the front of the table was decided on.

My mill table has a T-Slot along the front which I had used for movable stops that I found very useful so this was a reluctant decision, but the only alternative I could find would of reduced by Y travel to 4" which would of been a bigger loss.

I decided to use the T-Slot for mounting and make it removable so I could avoid any drilling or permanent modification to the mill. By making new custom mounting brackets for the scale I also hope to crimp a little extra range from the standard 12"/300mm iGaging scale. My mill's X-Axis travel is 315mm and I was too cheap to buy a 24"/600mm scale and cut it in half. A 12" scale is actually 305mm of travel and has about 10mm of the scale clamped in the supplied brackets at each end. By reducing the amount of the scale in the mounting to 3 or 4 mm at each end I figures I could gain an extra 10 to 15mm and cover the entire possible physical travel of my table with a "12 inch" scale.

So after machining up two new end bracket that attach to the T-Slot and had a shallow milled pocket for the scale ends to fit into, and a bracket for the reader that fixed to two unused tapped holes that were added by the previous owner I had an installation that required no additional modification to the mill and can be easily removed is necessary.

The components:

Installed:

Scale Bar Bracket:

Reader Bracket:

And with cover installed:

One down, two to go.