- Joined

- May 14, 2016

- Messages

- 54

Does anyone anodize aluminum?

If so can you tell me what I'm doing g wrong

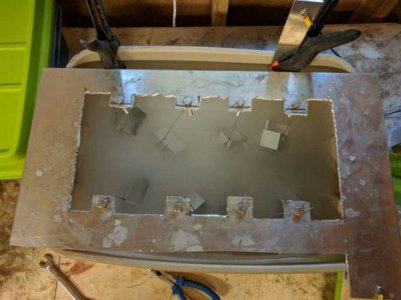

Process is the AL is polished, washed in degreaser, dunked in desmut then in the anodizing tank. 8 pieces at 15v 9amp 60 min

Then 30 min in dye and 30 min boiling water.

Yet they never come out consistent.

Temp of acid is 79.

Any help would be appreciated

If so can you tell me what I'm doing g wrong

Process is the AL is polished, washed in degreaser, dunked in desmut then in the anodizing tank. 8 pieces at 15v 9amp 60 min

Then 30 min in dye and 30 min boiling water.

Yet they never come out consistent.

Temp of acid is 79.

Any help would be appreciated