- Joined

- Sep 21, 2017

- Messages

- 117

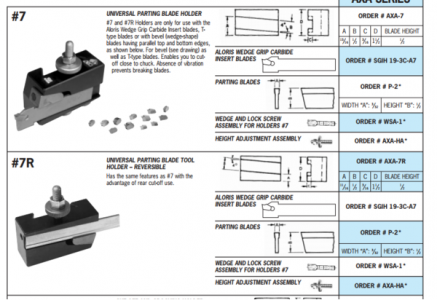

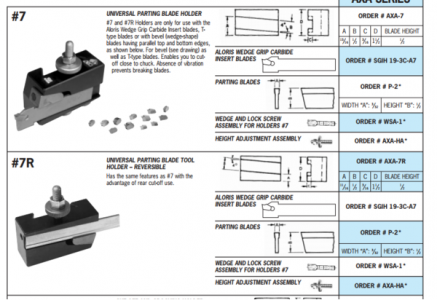

There must be something I'm missing here, but I don't get what the difference is between the Aloris #7 parting tool and the #7R? What is the 'rear cut-off use' under the #7R description?

This snapshot is taken from the Aloris tool catalog. I've been considering purchase of a parting tool holder for my Atlas/Craftsman 12" lathe. I think either style would work fine for me, I just want to understand the difference.

Thanks,

-Jake

This snapshot is taken from the Aloris tool catalog. I've been considering purchase of a parting tool holder for my Atlas/Craftsman 12" lathe. I think either style would work fine for me, I just want to understand the difference.

Thanks,

-Jake