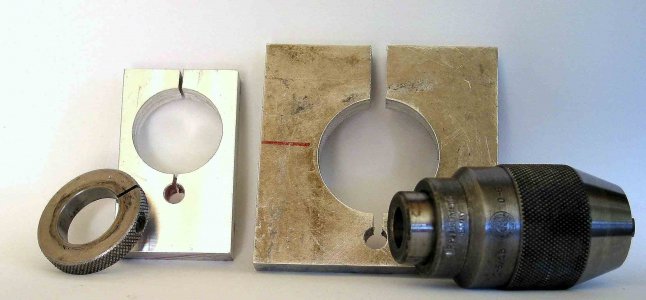

I had a mishap on the mill the other day and the R8 shank spun out of the chuck. The drill bit caught in mild steel as it broke through and crashed before I could react!

The problem is that I can't get the chuck to release the bit. Im guessing that the torque may have sprung the jaws to a point of not allowing the unscrewing mechanism to work.

I have placed the drill bit in the vise and put as much pressure as I felt comfortable with to brake it loose but no luck.

I don't care about the drill bit but would like to save the chuck if possible. Any ideas on how to fix this careless mistake?

The problem is that I can't get the chuck to release the bit. Im guessing that the torque may have sprung the jaws to a point of not allowing the unscrewing mechanism to work.

I have placed the drill bit in the vise and put as much pressure as I felt comfortable with to brake it loose but no luck.

I don't care about the drill bit but would like to save the chuck if possible. Any ideas on how to fix this careless mistake?