- Joined

- May 7, 2014

- Messages

- 776

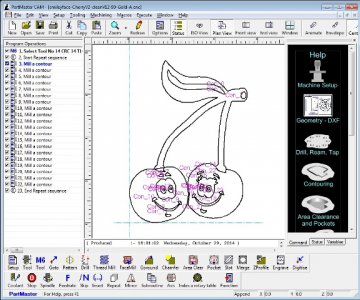

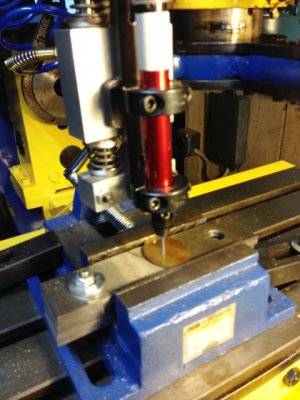

I found out that my Dolphin CAM PArtmaster V12 had an engraving module.... Yahoo. I could not wait to get an air pencil to mount on my Spindle setup. (as suggested here by our faithful HM gang!) It's still in work, and we are (sond and I) really new to about everything CNC , milling, and now engraving. So parts were ordered, boxes hit the door and I managed to get something together last week. It seems work work well and we're still experimenting w/ the design a bit. That's the fun/learn part so they say? (kidding- We're having fun!) .

The red air pencil was $25 or so on Amazon. "Hey Honey....Finally something under $1,000, can I buy it?" LOL. ( you know the drill for us newbs and tooling startup).

( you know the drill for us newbs and tooling startup).

CNC is so cool! The ability to take CAD to CAM and automate precision movements X, Y Z, I think is the cats meow!

I know it's basic 101 stuff- But we're really loving what you can do w/ all the software, hardware, and some imagination!. Love it!

The slide came from lm76.com What a cool site for stuff.

Ohhh Pic-

enjoy the fall weekend everyone!

CG

The red air pencil was $25 or so on Amazon. "Hey Honey....Finally something under $1,000, can I buy it?" LOL.

CNC is so cool! The ability to take CAD to CAM and automate precision movements X, Y Z, I think is the cats meow!

I know it's basic 101 stuff- But we're really loving what you can do w/ all the software, hardware, and some imagination!. Love it!

The slide came from lm76.com What a cool site for stuff.

Ohhh Pic-

enjoy the fall weekend everyone!

CG