-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ahp Alphatig 200x

- Thread starter roadie33

- Start date

- Joined

- Dec 11, 2014

- Messages

- 891

Got my new welding cart built for my new AHP Alphatig and customized Dual MIG 151 welder. Built it with 3 shelves in case I get a Plasma Cutter sometime soon. I painted it Hammered Copper with HVLP spray gun. Looks awesome in the daylight.

I noticed after I got the welders in their places that I needed to make some rod storage for the Tig rod and Stick.

Also need to make some kind of bar or something to clamp all of my welding clamps to.

The Kant Twist will need to be located elsewhere and I have a bunch of Bessey F style, some Vise grip F style clamps, regular swivel pad locking C clamps and to many regular C clamps to count. I almost need another cart just to hold all of the clamps.

I was thinking of getting some 2" PVC and capping one end, then attaching it to the legs on the cart for the TIG rod storage. Need to think of something else for the 6011 and 7018 rod.

I noticed after I got the welders in their places that I needed to make some rod storage for the Tig rod and Stick.

Also need to make some kind of bar or something to clamp all of my welding clamps to.

The Kant Twist will need to be located elsewhere and I have a bunch of Bessey F style, some Vise grip F style clamps, regular swivel pad locking C clamps and to many regular C clamps to count. I almost need another cart just to hold all of the clamps.

I was thinking of getting some 2" PVC and capping one end, then attaching it to the legs on the cart for the TIG rod storage. Need to think of something else for the 6011 and 7018 rod.

- Joined

- Mar 20, 2014

- Messages

- 440

I have the same hood and just used "standard" 2x4.25 lenses similar this one:

http://www.ebay.com/itm/diopter-3-0...488119?hash=item1eac955ab7:g:pCwAAOxyHIlTbj6g

The wire clip that holds the whole auto-darkening lens assembly in has enough 'give' to clamp a cheater lens as well...

I see you guys talking about using cheater lenses and have a question. Since I got into welding again after probably 20 years, I really have trouble seeing the weld puddle. I've been using some drug store reading glasses, but still have problems. Would the cheaters work better? I'm sure it is more convienient but what about actually helping to see what you're welding? Thanks, JR49

EDIT: Oh, and Roadie33, sorry for the hijack, I love the welding cart. Especially how you made the mounts for the gas bottles

- Joined

- May 18, 2014

- Messages

- 75

I like the cheaters better than using reading glasses. It helps keep me from getting dizzy when I look around the shop after I flip the hood up. I found that going 1x higher than what I use for reading glasses works good for the cheater, since you're only looking through it while welding.

- Joined

- Jun 26, 2013

- Messages

- 191

I see you guys talking about using cheater lenses and have a question. Since I got into welding again after probably 20 years, I really have trouble seeing the weld puddle. I've been using some drug store reading glasses, but still have problems. Would the cheaters work better? I'm sure it is more convienient but what about actually helping to see what you're welding?

I wear reading glasses to do any close work. To that end my shop safety glasses are actually magnified, and I find the cheater lens in the hood is the only thing that lets me get a good view of the puddle.

- Joined

- Dec 11, 2014

- Messages

- 891

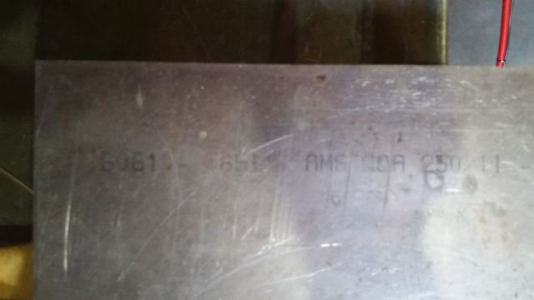

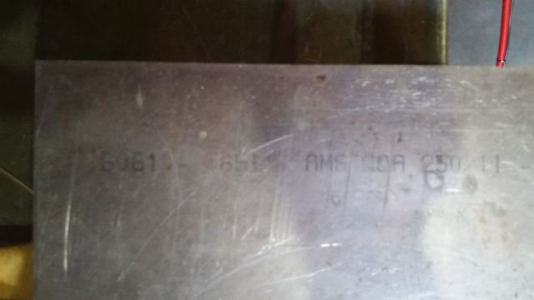

I tried to finally do some AC Aluminum practice welding today and it did not turn out very pretty. Don't know if it was me, the metal or the welder. Have had good results with DC Steel.

Set on AC, 100 Amps, Argon at 25, tried AC Freq 120 and 150, Balance around 40%. No difference.

Here are some pics of what I was trying to weld, the settings and how it turned out. Any help would be greatly appreciated on what I was doing wrong so I can fix it.

Set on AC, 100 Amps, Argon at 25, tried AC Freq 120 and 150, Balance around 40%. No difference.

Here are some pics of what I was trying to weld, the settings and how it turned out. Any help would be greatly appreciated on what I was doing wrong so I can fix it.

- Joined

- May 18, 2014

- Messages

- 75

That looks like you had no shielding for your arc. Were you getting sparks? What cup are you using with 25cfh argon flow? I haven't done any AL with my machine yet, but 25cfh seems really high unless you're using a large cup like a #12. Too much argon flow with a small cup will blow the shielding gas off your arc and draw in outside air. Try backing the Argon down to about 15cfh.

- Joined

- Dec 11, 2014

- Messages

- 891

I was using 3/32" 2% Lanth Tungsten with 3/32" 4043 Filler and a gas lens with #7 cup.

I tried from 10 to 25 on Argon and no difference doing that.

I was wondering if the AC Balance is way off and trying to do to much cleaning?

I might try different settings again tonight and see what happens. Ran out of time to do it yesterday.

Really need to get this figured out in case it's the welder and I need to contact them for warranty.

I tried from 10 to 25 on Argon and no difference doing that.

I was wondering if the AC Balance is way off and trying to do to much cleaning?

I might try different settings again tonight and see what happens. Ran out of time to do it yesterday.

Really need to get this figured out in case it's the welder and I need to contact them for warranty.

Ditto on 15cfh with a gas lens. Is that 1/4" thick aluminum? If so you need to open the machine up to 200 amps to get enough heat. Your ac balance should be close where it is. Also the ac frequency should be turned down to 40 to 80 assuming it is that thick of plate. The higher frequency tends to be for lighter sheet metal. And are you using the foot pedal?