- Joined

- Jul 5, 2017

- Messages

- 10

Hello.

I'm new to machining. I want to make a stainless steel version of the Aeropress coffee maker (actually just the two parts on the left):

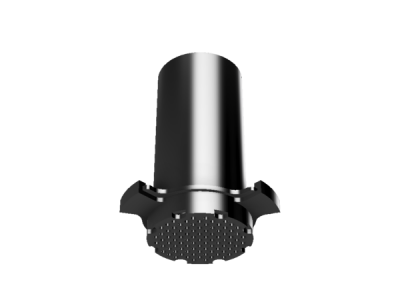

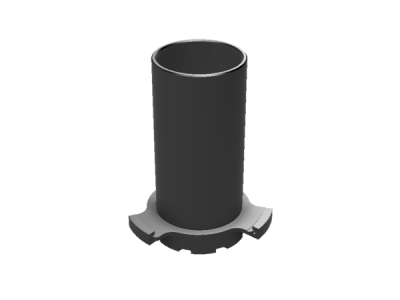

Here are images of my desgin (happy to supply the actual files if needed):

I plan to weld the part of the left to a 5" long 2.5" diameter tube of stainless steel.

I have access to Tormach CNC Mill. Which I think is a lightweight machine but that's just what I've been told.

I've been researching the different types of stainless steel and found 303, 304, and 316. From what I've read, 304 is the hardest to machine so I can cross that off the list. 303 is the easiest but is difficult to weld which is how I was planning on attaching the left part to the tube. That leaves 316 which I've read is a little easier than 304.

My question is, how difficult is it to machine may parts out of stainless steel and is it out of the question for a newbie to be able to do with a Tormach CNC Mill?

I'm new to machining. I want to make a stainless steel version of the Aeropress coffee maker (actually just the two parts on the left):

Here are images of my desgin (happy to supply the actual files if needed):

I plan to weld the part of the left to a 5" long 2.5" diameter tube of stainless steel.

I have access to Tormach CNC Mill. Which I think is a lightweight machine but that's just what I've been told.

I've been researching the different types of stainless steel and found 303, 304, and 316. From what I've read, 304 is the hardest to machine so I can cross that off the list. 303 is the easiest but is difficult to weld which is how I was planning on attaching the left part to the tube. That leaves 316 which I've read is a little easier than 304.

My question is, how difficult is it to machine may parts out of stainless steel and is it out of the question for a newbie to be able to do with a Tormach CNC Mill?