- Joined

- Dec 30, 2011

- Messages

- 81

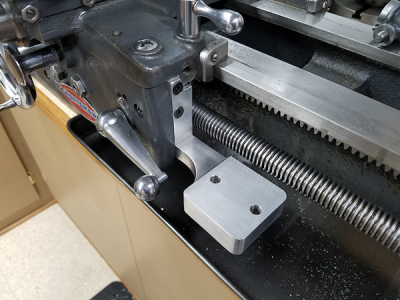

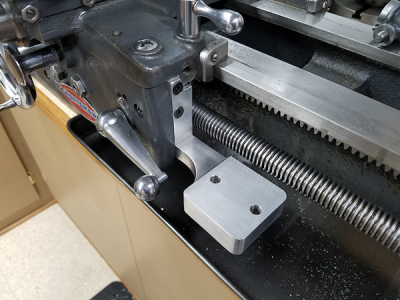

Just finished adding a Trav (A) Dial to my Craftsman 12"x 24" lathe, and thought I would share some pictures in case anyone else was thinking about doing this. I was very lucky to get this one at a great price, wish I could afford to put them on all my machines. Love keeping my toys old school, without DRO's, since I do not make a living with them.