OK, I'm taking a break because I think I'm chasing my tail a bit trying to align this thing. This means opinions welcome. :LOL:

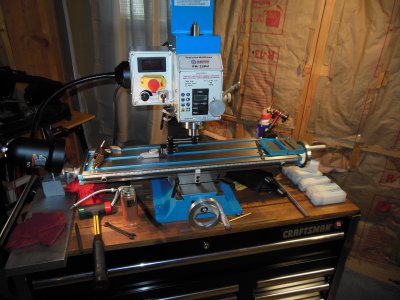

I checked the spindle to column and well, I think it's OK the way it is. I've not used this method before, so someone check my figures. Stuck a half-inch piece of stainless in a R-8 collet and here is what I came up with:

About a half inch below the column, I can detect no movement on my DTI. Moved the head up 4" and I get about a .00075" swing on the indicator. I 'assume' this is good enough? This was from the factory BTW.

View attachment 66577

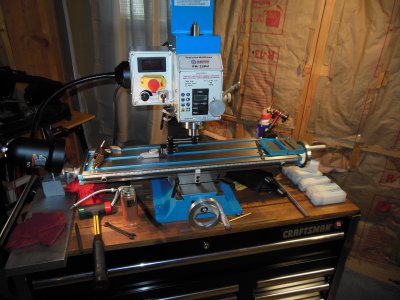

Then I set up to check the table to column. Put my little DTI holder in a 3/8" collet and lower the head to so I get needle movement. Zero the dial, then go to swing over to the left side of the table. Oh oh... the fixture hits the table swinging over?!?! Yipes!

anic:

Background: When the mill arrived, the stand was strapped onto the top of the machine's crate, and had collapsed the top cover and was trying to get cozy with the mill. I'm thinking the column took a big hit. It looks like the column is tilted like crazy to the left.

So after I calm down, I grab a 10mm allen wrench and attempt to loosen the four bolts holding the column to the base casting. Don't know the torque setting on these grade 8 bolts, but I had to take a hammer to the allen wrench to get these suckers loose. That was after I bent my pump handle for my shop hoist trying to use it as an extender. Sheesh...

Anyway, after much fiddling around I managed to get the x-axis to just over a half thou swinging a 7" radius. So does this mean I'm under a thou if I translate 14" in the x-axis?

View attachment 66578

I'm done for now. Need coffee and something to munch on. I think I screwed up though, in that I probably should have checked/trammed the Y-axis first because if it needs shims I'm going to loose my X-axis alignment when I attempt to stick those suckers in. :banghead:

Oh well, I'll mess with it Thursday as I'm off this week and through New Years Day.

Enjoy tomorrow everyone,

Bill

anic: