- Joined

- Apr 4, 2013

- Messages

- 664

Hi folks,

I finally decided to bite a bullet and get a new mill, and just placed and order for a PM-833TV.

Have a few questions:

1) I can't find the dimensions for the base footprint and mounting hole spacing. I'm going to weld a stand for it (didn't get the PM base, since I want to have drawers under the machine (shop space is very limited). I'd like to have the base ready by the time the machine comes, so I'd appreciate if someone could either point me to the official drawing, or measure the hole spacing and base width/depth.

2) Is the end of Z lead screw accessible from the top accessible from the top of the machine? I will be adding a power feed of some sorts to it, and ideally I'd want to use a servo motor driving the lead screw, rather than dealing with the bevel gears and have it stick out on the side (I have a stepper motor on my current SIEG SX4, and much prefer that arrangement than the standard PM way of dealing with Z power feed).

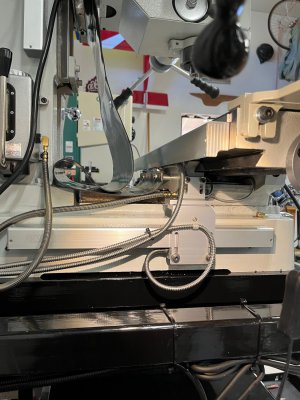

3) What DRO scales do you use on your PM-833? By the looks of it, it doesn't look like there is enough space on the Y axis for a glass scale, but PM has an option for a glass scale DRO. I'm curious how it's mounted. The other option are magnetic scales (they look like rebranded EMS/Electronica scales, and $1000 is actually not a bad price for that set). If someone has that option, could you please post some photos? If the installation looks reasonable, I might just order that and replace the EMS display with TouchDRO (for obvious reasons ). Also, what is the reference mark scheme on those scales? I.e. does the magnetic tape have standard EMS "mark every 50mm"?

). Also, what is the reference mark scheme on those scales? I.e. does the magnetic tape have standard EMS "mark every 50mm"?

4. Finally, what are the mods that people do to these machines? PM-833T looks to be very similar to the mil that Stefan Gotteswinter used to have, so I have some ideas for the mods, but curious to see what current owners ended up doing.

Also, as a bonus question: how well were the gibs fitted to the machine when you got it? I haven't owned any PM machines yet (both of my larger mills were Grizzly, and they needed a LOT of scraping on the gibs, so just trying to get my expectations calibrated for a PM mill).

Thank you in advance to any info

Regards

Yuriy

I finally decided to bite a bullet and get a new mill, and just placed and order for a PM-833TV.

Have a few questions:

1) I can't find the dimensions for the base footprint and mounting hole spacing. I'm going to weld a stand for it (didn't get the PM base, since I want to have drawers under the machine (shop space is very limited). I'd like to have the base ready by the time the machine comes, so I'd appreciate if someone could either point me to the official drawing, or measure the hole spacing and base width/depth.

2) Is the end of Z lead screw accessible from the top accessible from the top of the machine? I will be adding a power feed of some sorts to it, and ideally I'd want to use a servo motor driving the lead screw, rather than dealing with the bevel gears and have it stick out on the side (I have a stepper motor on my current SIEG SX4, and much prefer that arrangement than the standard PM way of dealing with Z power feed).

3) What DRO scales do you use on your PM-833? By the looks of it, it doesn't look like there is enough space on the Y axis for a glass scale, but PM has an option for a glass scale DRO. I'm curious how it's mounted. The other option are magnetic scales (they look like rebranded EMS/Electronica scales, and $1000 is actually not a bad price for that set). If someone has that option, could you please post some photos? If the installation looks reasonable, I might just order that and replace the EMS display with TouchDRO (for obvious reasons

4. Finally, what are the mods that people do to these machines? PM-833T looks to be very similar to the mil that Stefan Gotteswinter used to have, so I have some ideas for the mods, but curious to see what current owners ended up doing.

Also, as a bonus question: how well were the gibs fitted to the machine when you got it? I haven't owned any PM machines yet (both of my larger mills were Grizzly, and they needed a LOT of scraping on the gibs, so just trying to get my expectations calibrated for a PM mill).

Thank you in advance to any info

Regards

Yuriy