- Joined

- Jan 22, 2014

- Messages

- 578

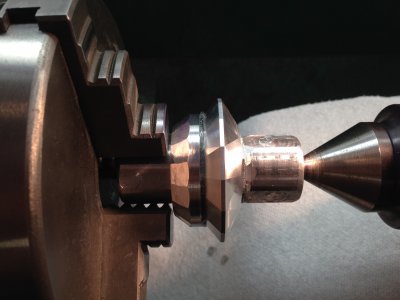

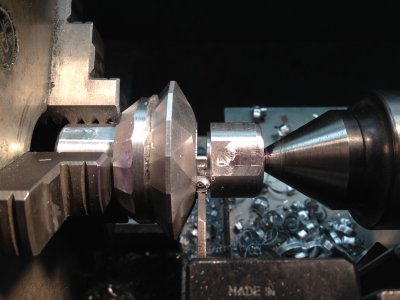

After I completed my Rotary Table (RT) angle plate fixture, I got to thinking about some projects that I could do with it. The ability to have precision access to another couple of axis is empowering. We all know X, Y and Z axis, but I don’t know if there is a term for these additional ones, so I’m calling them Axis R (rotation) and Axis RA (rotation + angle). Feel free to correct me if I’m wrong.

My wife and I like to frequent local gem shows (her jewelry/me rocks). I’ve always admired the craftsmanship that goes into cutting gemstones. I thought that the RT w/ Angle Plate should make it possible, so I decided to try and cut my own Diamond.

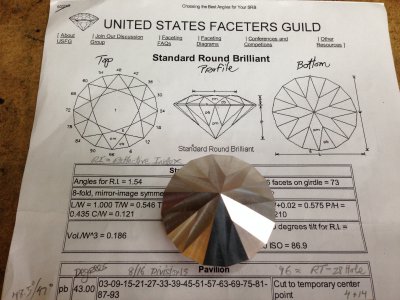

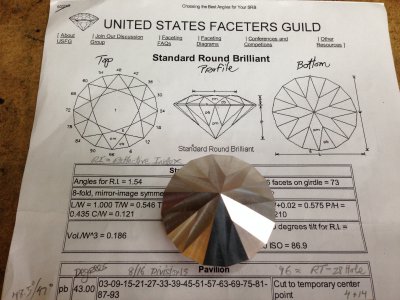

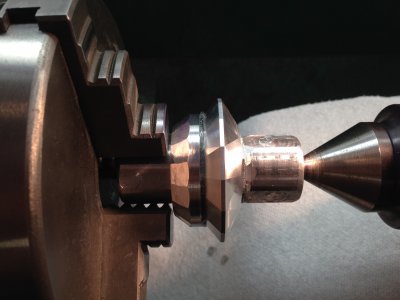

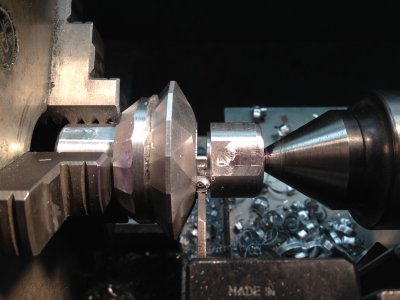

I had a leftover piece of 2” aluminum round bar and I thought that it would be a good starting point to practice on. I did a lot of research to find anything I could on diamond cutting. I needed angles, sizes, proportions, sequencing, lapping and polishing techniques. I found some great information in a gemologist club newsletter that gave me everything I needed. From there I figured out their lingo and formulas and I made a plan. I figured out a way to reliably hold the piece so I could accurately cut the 73 facets, a simple indexing system to retain continuity from end to end, and finally a way to finish it. Aluminum is so soft; you really have to be careful not to lose the crisp edges.

I included some build and finish pics, and the spec sheet I used with all of the info. I hope you like it.

Factiod: I calculated the weight of my diamond based on the specific gravity of aluminum and dimensions and it comes to about 450 Karats. A real diamond of the same size, cut and weight would cost 2 to 200 million dollars depending on the color, clarity, etc..

My wife and I like to frequent local gem shows (her jewelry/me rocks). I’ve always admired the craftsmanship that goes into cutting gemstones. I thought that the RT w/ Angle Plate should make it possible, so I decided to try and cut my own Diamond.

I had a leftover piece of 2” aluminum round bar and I thought that it would be a good starting point to practice on. I did a lot of research to find anything I could on diamond cutting. I needed angles, sizes, proportions, sequencing, lapping and polishing techniques. I found some great information in a gemologist club newsletter that gave me everything I needed. From there I figured out their lingo and formulas and I made a plan. I figured out a way to reliably hold the piece so I could accurately cut the 73 facets, a simple indexing system to retain continuity from end to end, and finally a way to finish it. Aluminum is so soft; you really have to be careful not to lose the crisp edges.

I included some build and finish pics, and the spec sheet I used with all of the info. I hope you like it.

Factiod: I calculated the weight of my diamond based on the specific gravity of aluminum and dimensions and it comes to about 450 Karats. A real diamond of the same size, cut and weight would cost 2 to 200 million dollars depending on the color, clarity, etc..