Yours looks very similar to mine. Maybe a few differences on the front of the apron.

Yours should clean up nicely and provide great service once you get it back operational. The old style split bearings that hold the spindle in the headstock are very easy to take apart and replace if needed. Very likely you could shim and scrape your existing bearings, if anything is worn to badly. If it were me, I would replace the tiny oil cups atop the bearings, with a couple of lunkenheimer style drip oilers, that you can purchase on line. Gives you a lot more oil holding and librication capacity than those little git oilers in your photos.

I think it would be interesting to take some actual measurements across the width of the ways and compare that to the later model SB 9's - just to see how different these actually are.

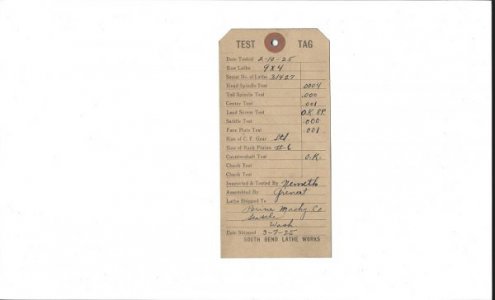

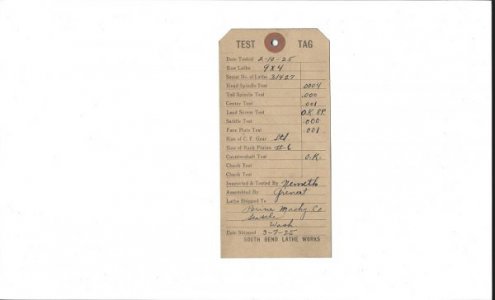

Here's the card I got with my SB 9. This came from the factory , apparently is the inspection /QC card from final assembly. I also have the original bill of sale, where the first owner purchased the lathe from Petrine Machinery, a local Seattle hardware and machinery supplier back in 1925. I bought the machine from the guy's grandson, found out it's been in the one family since new - and only used for a few years before going into storage. So never had to chase down manufacture date. As far as wear goes - there isn't any! Well, there is a little bit of wear on the ways - some of the flaking is partially worn off in places. Tsk, tsk.

The real amazing thing about this lathe is that it sat on Craig's list for weeks. But was covered in dust, dried machine oil, and sawdust so nobody went to look at it. I passed it up several times, then finally looked closely at the on line photos out of frustration at not finding a decent machine for sale, at the time. Caught a glimmer of flaking in the photos and went to see it person. Couldn't believe what condition it was in - underneath all the decades of cob webs and dust.

The original owner used it mostly for woodworking - I think the combination of sawdust and machine oil made a terrific preservative. Haven't got it running yet, need to build up or buy a countershaft to mount an electric motor - the grandson - by now retired, took it to the dump a few years ago as "it was collecting cob webs" in his garage! Aaarrrghh.

-glenn