- Joined

- Nov 23, 2014

- Messages

- 2,632

Santa brought me an early present this year, a 5-C lever style collet closer for my Grizzly G0709 lathe! Grizzly does not sell a collet closer specifically for the G0709, but they do sell one for a 14 x 40 lathe (model H5948). The price is right at $270. The regular price is $450 so these are likely priced for close out.

Ted, a fellow HM member, took the leap and bought the H5948 model and found that the hub adapter fits perfectly on the spindle of the G0709 lathe. The draw bar tube is too long by about 4” as received, but that’s what our shops are made for!

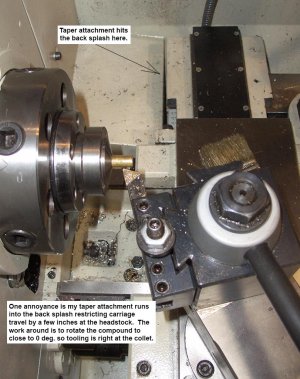

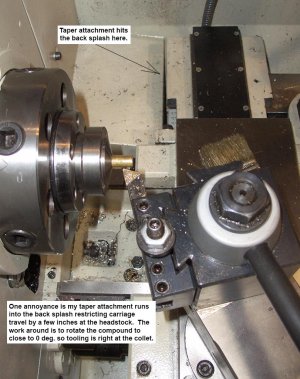

Ted came up with an overall length of 21 ¼” for the draw bar tube. I cut mine to 21 ½” figuring it’s easier to remove length than to put it back on. The photos tell the story, install the adapter to the spindle, set the adjusting hub in place, set the locking yoke and collars on the end of the draw bar tube. I measured the distance between the 5MT to 5-C adapter w/collet threaded in place and the spindle to determine how much shorter to make the draw bar tube.

A couple of other mods were reinforcing the headstock back cover with a couple of ½” thick aluminum straps. The cover is about ¼” aluminum, I was a little nervous about cracking the cover over time and went the over-engineered route. The pivot brackets had to be shallowed up to fit as the locking yoke ended up an inch or so closer to the cover. Pretty simple mill/band saw mods. I used a drum sander on the drill press to open up the spindle hole in the cover by about 0.060” to get more clearance to the hub adapter.

Ted took an easier, more robust approach by attaching the pivot bracket to the headstock cover bracket boss. He turned a new boss to get the correct thread for the pivot bracket. The biggest difference to our installs is his collet lever points down, mine points up. Both work great, just a matter of preference.

The closer is pretty simple to remove when not in use, just pull one M8 cap screw on the pivot bracket and slide the attachment off the lathe. I made a spanner wrench of sorts for tightening/loosening the hub adapter to the back of the spindle. That and the cover need to be removed to access the ball oilers on the banjo bracket. Sure wish Grizzly would have made a door in the cover so it doesn’t have to be removed to access those ball oilers; maybe a future shop project . . .

Ted, a fellow HM member, took the leap and bought the H5948 model and found that the hub adapter fits perfectly on the spindle of the G0709 lathe. The draw bar tube is too long by about 4” as received, but that’s what our shops are made for!

Ted came up with an overall length of 21 ¼” for the draw bar tube. I cut mine to 21 ½” figuring it’s easier to remove length than to put it back on. The photos tell the story, install the adapter to the spindle, set the adjusting hub in place, set the locking yoke and collars on the end of the draw bar tube. I measured the distance between the 5MT to 5-C adapter w/collet threaded in place and the spindle to determine how much shorter to make the draw bar tube.

A couple of other mods were reinforcing the headstock back cover with a couple of ½” thick aluminum straps. The cover is about ¼” aluminum, I was a little nervous about cracking the cover over time and went the over-engineered route. The pivot brackets had to be shallowed up to fit as the locking yoke ended up an inch or so closer to the cover. Pretty simple mill/band saw mods. I used a drum sander on the drill press to open up the spindle hole in the cover by about 0.060” to get more clearance to the hub adapter.

Ted took an easier, more robust approach by attaching the pivot bracket to the headstock cover bracket boss. He turned a new boss to get the correct thread for the pivot bracket. The biggest difference to our installs is his collet lever points down, mine points up. Both work great, just a matter of preference.

The closer is pretty simple to remove when not in use, just pull one M8 cap screw on the pivot bracket and slide the attachment off the lathe. I made a spanner wrench of sorts for tightening/loosening the hub adapter to the back of the spindle. That and the cover need to be removed to access the ball oilers on the banjo bracket. Sure wish Grizzly would have made a door in the cover so it doesn’t have to be removed to access those ball oilers; maybe a future shop project . . .