- Joined

- Dec 3, 2013

- Messages

- 1,844

I need another project like I need a hole in my head but I have another project for my business that has parts that screamed 3D printer. A few months ago I purchased a Creality CR-10 because of the low cost to build volume. Its a nice printer for figurines and doo-dads but after many hours of tweaking I'm not getting satisfactory results in higher temp materials at reasonable print speed. I get a lot of ghosting especially in the Y axis at anything above 30 mm/s which is unsatisfactory for print times. The moving mass of the table and un-braced design of the Z axis rails lends to too much shaking. I also had problems with missed steps until I increased the stepper driver voltage on the Y axis motor.

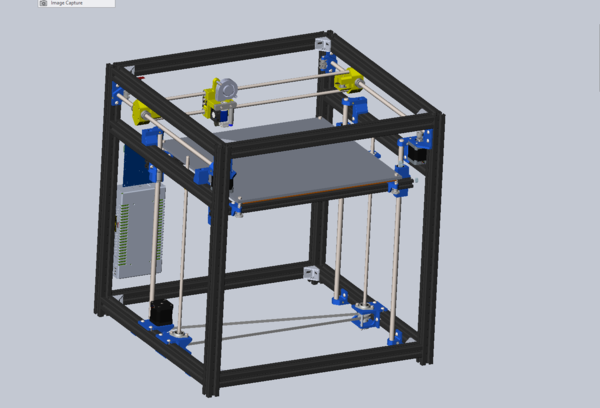

After much research and looking at off the shelf printers I decided to just build what I want. I'm not recreating the wheel by any means. My build is based off the HyperCube Evolution which is a corexy design which is a remix of someone elses design . https://www.thingiverse.com/thing:2254103 . I have up-scaled so my build has a build volume of 400mm x 400mm x 400mm.

Specifications are:

CoreXY design

400mm x 400mm x 400m build area

30mm aluminum extrusions for the frame.

20mm aluminum extrusions for the built table frame

Nema 17 62 oz in 400 step motors on the X, Y & Z axis

Dual Z screws driven by a single motor

GT2 2mm pulleys with 6mm belts

12mm linear rails on the Z axis and 10mm on the X & Y

E3D-v6 24v hot end

Titan Extruder (will start as a Bowden setup)

120vac silicon heater for the bed

1/4" MIC-6 aluminum build table

Auto bed leveling

Duet Ethernet controller

24v 20A power supply

Currently not planning on a display as I run my prints from my desktop PC.

CAD Model

Parts printed on the CR-10. Printed in PETg

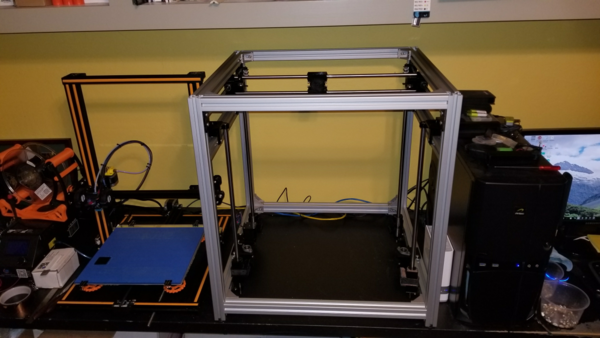

Progress so far. Parts are still trickling in. Bed heater and optical limit sensors are on a slow boat from China and will not be here until December.

After much research and looking at off the shelf printers I decided to just build what I want. I'm not recreating the wheel by any means. My build is based off the HyperCube Evolution which is a corexy design which is a remix of someone elses design . https://www.thingiverse.com/thing:2254103 . I have up-scaled so my build has a build volume of 400mm x 400mm x 400mm.

Specifications are:

CoreXY design

400mm x 400mm x 400m build area

30mm aluminum extrusions for the frame.

20mm aluminum extrusions for the built table frame

Nema 17 62 oz in 400 step motors on the X, Y & Z axis

Dual Z screws driven by a single motor

GT2 2mm pulleys with 6mm belts

12mm linear rails on the Z axis and 10mm on the X & Y

E3D-v6 24v hot end

Titan Extruder (will start as a Bowden setup)

120vac silicon heater for the bed

1/4" MIC-6 aluminum build table

Auto bed leveling

Duet Ethernet controller

24v 20A power supply

Currently not planning on a display as I run my prints from my desktop PC.

CAD Model

Parts printed on the CR-10. Printed in PETg

Progress so far. Parts are still trickling in. Bed heater and optical limit sensors are on a slow boat from China and will not be here until December.